Motion Control Technology by SANYO DENKI AMERICA

motioncontrol.blog is operated by SANYO DENKI AMERICA and shares motion control engineering insights for industrial applications.

Over the years, 3D printing technology has evolved from its humble beginnings in workshops, labs, and classrooms to playing a crucial role in industrial manufacturing. Today, some advanced 3D printers can seamlessly integrate into production lines, producing finished parts directly within the production workflow. These machines now work with a diverse range of materials, including plastics and metals, enabling production-scale end parts with exceptional accuracy and surface finish.

As 3D printing technology matures, the choice of motors has become critical. While traditional stepper motors with encoder have been the go-to choice, AC servo motors with EtherCAT communication protocol are gaining prominence due to their superior performance and precision. Let’s explore their applications:

Stepper motors are commonly used for precise movement along the X, Y, and Z axes. Their encoder-based feedback ensures accurate positioning, but for 3D printer that produce intricate designs and complex geometries, AC servo motors are used for high precision and high accuracy.

Servo motors provide precise control over the extruder’s movements, ensuring consistent material flow and layer deposition. This precision is vital for maintaining high print quality and avoiding defects.

Some advanced 3D printers incorporate rotational axes for printing on curved or cylindrical surfaces. Servo motors enable accurate control of these rotations, expanding the printer’s capabilities.

In multi-material 3D printers, servo motors are used in tool changing systems to switch between different print heads or tools with high precision, allowing for complex and multi-material prints.

Servo motors drive the mechanisms for automated bed leveling, ensuring the print bed is perfectly aligned before printing begins. This is essential for achieving uniform layer height and high-quality prints.

Servo motors facilitate the movement of finished 3D printed products from the printing area to the production line, ensuring smooth and efficient transitions in an automated manufacturing process.

By integrating these advanced motor control solutions, 3D printers can achieve superior performance, reliability, and versatility, meeting the demands of modern manufacturing and prototyping.

Servo motors offer several advantages for 3D printers, including:

Thanks to their built-in feedback loop, servo motors provide precise control over positioning, which improves print quality and ensures dimensional accuracy.

Servo motors maintain uniform torque across all speeds, allowing for faster printing with enhanced control.

With the capability to deliver higher torque at higher RPMs, servo motors ensure greater accuracy and repeatability in high-speed movements.

At SANYO DENKI, we offer a comprehensive lineup of motion control solutions. We provide amplifiers with EtherCAT support, indexers, and analog/pulse communication types. Our servo motor lineup features a size range of 40, 60, 80, 86, 100, 130 mm² and more. To achieve synchronized motion across up to 8 axes—from the upper controller down to the motor level—all controlled by a single motion controller. Our motion controller comes in three variants: the standard model S100, the IoT model S200, and the high-end controller S500 that can control a maximum of 64 motor axes.

Our complete lineup includes reliable and cost-effective F2 stepper system, and closed-loop PB stepper system, and more. Our motion control solution enables seamless integration into advanced 3D printers, providing the precision and reliability required for cutting-edge applications.

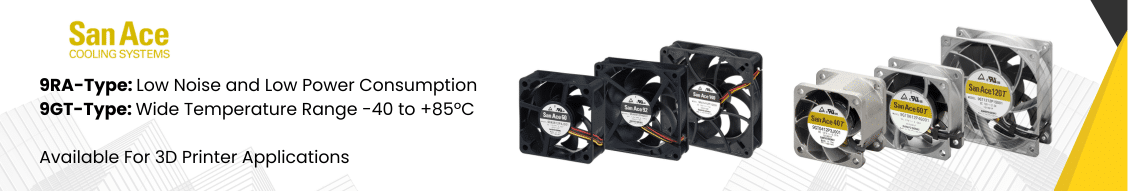

Additionally, SANYO DENKI offers cooling solutions for 3D printers. We provide the 9RA-type DC Cooling Fans for powerful cooling performance with low acoustic noise, and the 9GT-type fan with a wide temperature range, capable of operating at temperatures up to +85ºC. Explore our range of cooling fans to find the perfect solution for your 3D printing needs.

Whether you’re designing cutting-edge 3D printers or optimizing existing systems, our expertise ensures smooth motion control. Feel free to explore our range and elevate your 3D printing capabilities.

This article is part of SANYO DENKI AMERICA’s motion control engineering knowledge base, sharing practical insights used in real-world servo and motion control applications.

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.