Motion Control Technology by SANYO DENKI AMERICA

motioncontrol.blog is operated by SANYO DENKI AMERICA and shares motion control engineering insights for industrial applications.

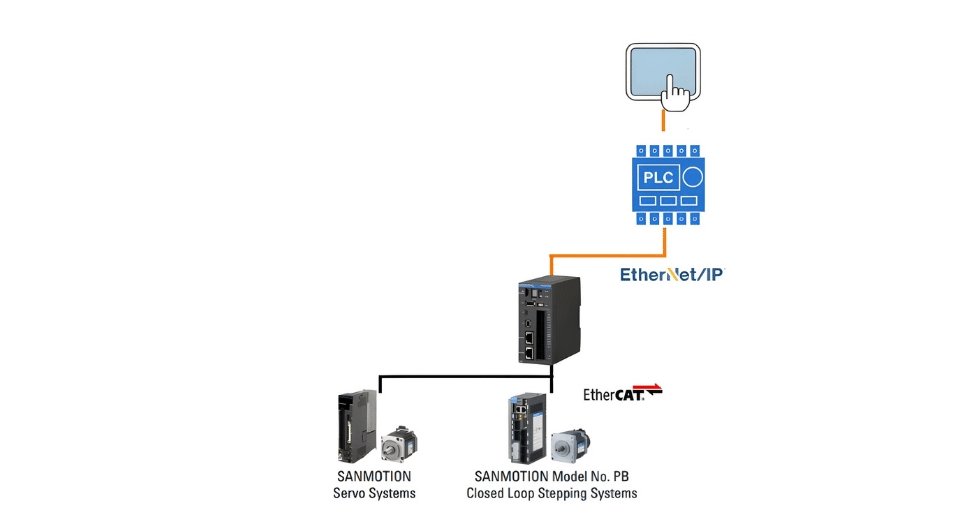

SANMOTION uses EtherCAT for the real-time inner loop to drives—that’s how you get deterministic multi-axis performance. When your machine standardizes on an EtherNet/IP PLC, SANMOTION C bridges the two: you keep your EtherNet/IP tags and workflows at the supervisory layer while motion executes over EtherCAT to SANMOTION servo or stepper drives. Result: EtherNet/IP motion control without re-architecting the machine—and predictable profiles, tuning, and settle behavior where it matters.

The PLC uses EtherNet/IP motion control to send start/stop, mode, and target position/velocity, and to read axis-ready, in-position, and alarms. SANMOTION C acts as the bridge: it exposes an EtherNet/IP interface to the PLC and manages motion over EtherCAT to SANMOTION servo or stepper drives. Drives and motors remain on the real-time motion bus, so profiles, tuning, and following-error limits behave predictably. This split keeps plant-level coordination on EtherNet/IP and preserves motion performance where it counts.

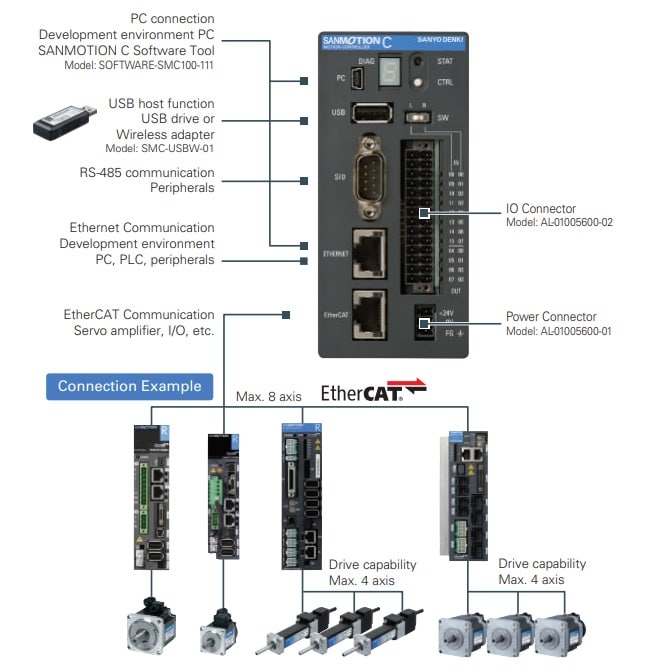

Configuration example with S100 model.

These outcomes are achieved using SANMOTION C for EtherNet/IP motion control at the supervisory layer and EtherCAT for inner-loop motion.

Conformance and interoperability documents are available upon request.

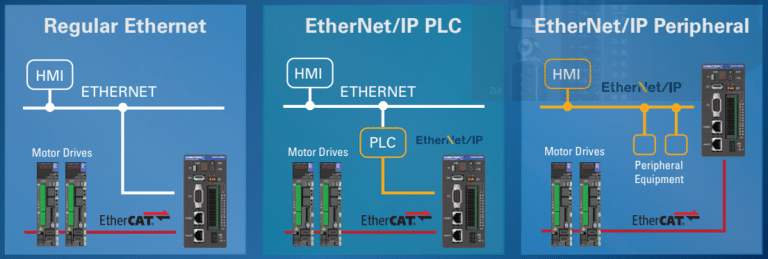

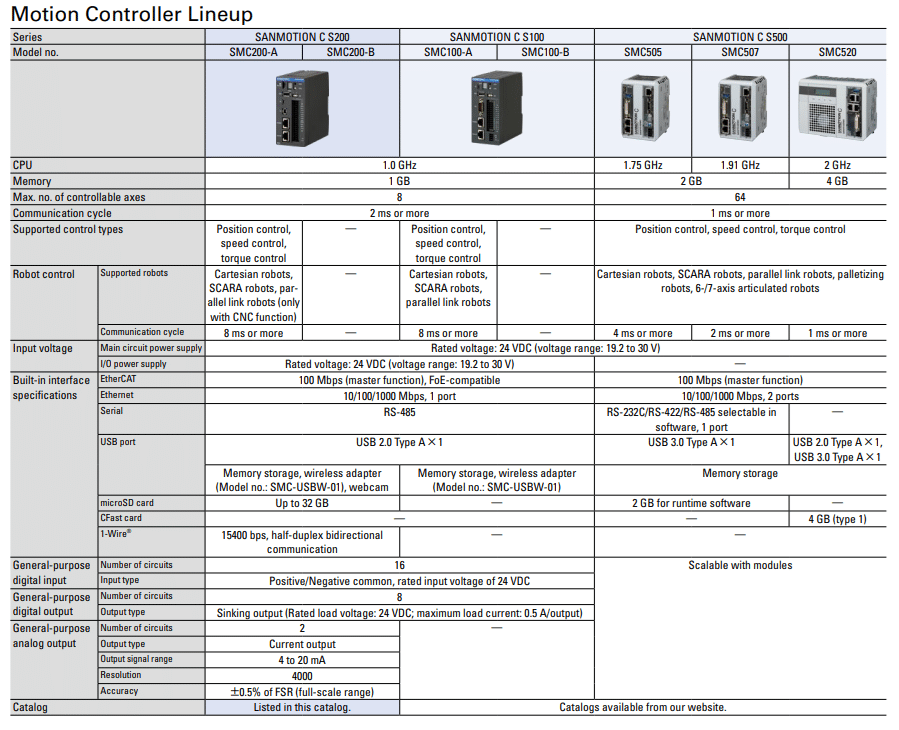

Choose the controller that matches your network and application needs.

If you want EtherNet/IP motion control at the PLC and deterministic motion without re-architecting your machine, use SANMOTION C as the bridge. You’ll integrate quickly, keep your control standards, and hit predictable cycle times.

Contact SANYO DENKI AMERICA for a quick tag-mapping review or a bench test using your PLC.

This article is part of SANYO DENKI AMERICA’s motion control engineering knowledge base, sharing practical insights used in real-world servo and motion control applications.

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.