Motion Control Technology by SANYO DENKI AMERICA

motioncontrol.blog is operated by SANYO DENKI AMERICA and shares motion control engineering insights for industrial applications.

“Smart motion” is easy to say. The harder part is keeping multi-axis machines stable when complexity and tight timing turn small disturbances into rare, expensive failures.

What if the machine stops only once every few weeks, and you can’t reproduce it on command?

That’s when a motion controller stops being “control hardware” and becomes an uptime tool.

Smart motion becomes a real requirement when coordinated axes and tight cycle timing leave no room for guesswork.

Most teams can tune motion to run. The expensive part is diagnosing rare events:

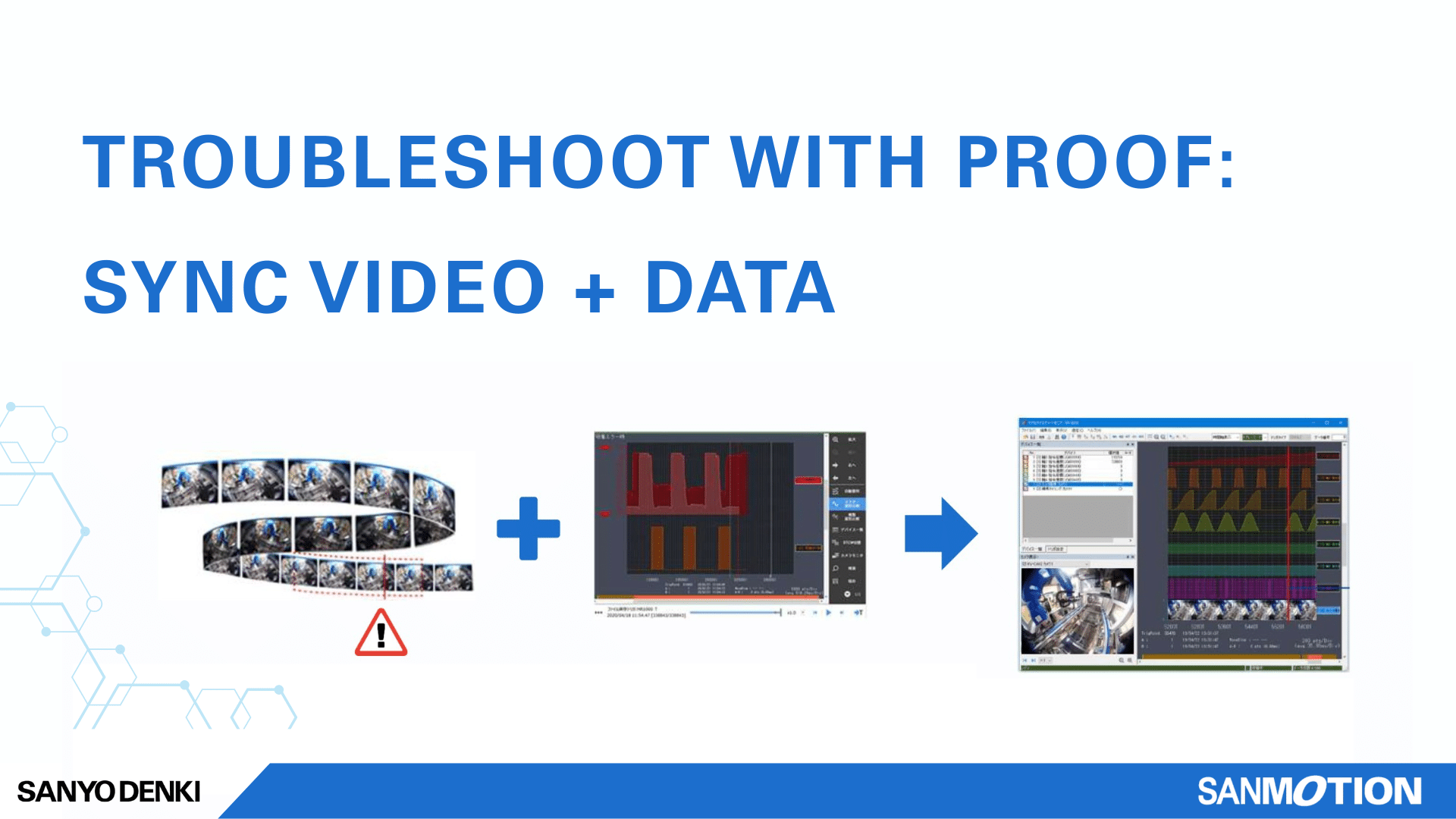

If your premise is “we can debug this with traces,” what if the trace doesn’t explain the physical behavior you saw (or didn’t see)? Visual context is often the missing piece.

One of the most practical shifts in modern motion control is moving from “data only” troubleshooting to visual + numerical correlation.

SANMOTION C S300 supports this approach: it can record equipment operation video synchronized with motion data from connected servo motors and servo amplifiers.

Why that matters in practice:

If you’ve ever had to explain an intermittent event to production, quality, or a customer, you already know why this matters.

For multi-axis equipment, “smart” still has to be fast and deterministic.

The point isn’t “more protocols.” It’s that multi-axis machines inevitably grow: more sensors, more stations, more interlocks, more coordination. Planning for that growth up front prevents rebuilds later.

If your equipment is network-connected (even indirectly), then “what if someone shouldn’t be able to touch this?” is a real question.

The S300 is designed with enhanced protection against unauthorized software access, and its controller software can be updated to help maintain a secure environment.

That’s exactly the gap SANMOTION C S300 is designed to address: Combining deterministic multi-axis control with practical tools to shorten troubleshooting when something unexpected happens in the field.

If your equipment has multiple coordinated axes, the real differentiator isn’t just whether it can run fast—it’s whether you can keep it running when something unexpected happens in the field.

If your goal is to reduce downtime and shorten debugging cycles—not just hit performance targets—S300 is worth a closer look.

This article is part of SANYO DENKI AMERICA’s motion control engineering knowledge base, sharing practical insights used in real-world servo and motion control applications.

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.