Motion Control Technology by SANYO DENKI AMERICA

motioncontrol.blog is operated by SANYO DENKI AMERICA and shares motion control engineering insights for industrial applications.

When a production line stops unexpectedly, everything behind it collapses—output, delivery schedule, profit, and sometimes the customer relationship. Anyone who has worked around servo-driven machinery knows this pain: a single motor or amplifier fault can freeze an entire process.

Factories have always tried to stay ahead of failures. But the traditional playbook—run it until it breaks or replace parts on a calendar—doesn’t match the realities of today’s high-speed, high-precision production. As machines become more complex, the cost of “not knowing” what’s happening inside a servo system grows quickly.

That gap is what predictive maintenance is designed to close.

In most factories, servo maintenance still follows two familiar approaches.

Corrective maintenance

Waits for a failure, then reacts.

It’s simple, but a breakdown means unplanned downtime, scrap, and lost output.

Preventative maintenance

Schedules replacements on fixed intervals.

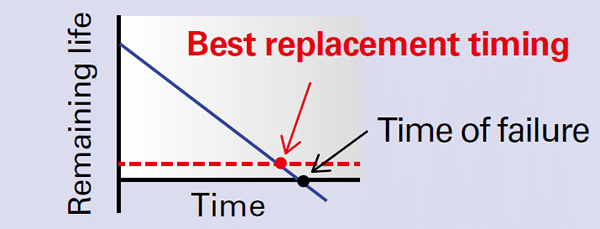

Better—yet still flawed. Parts might be swapped too early, wasting money, or too late, leaving room for unexpected failures between planned service cycles.

Predictive maintenance

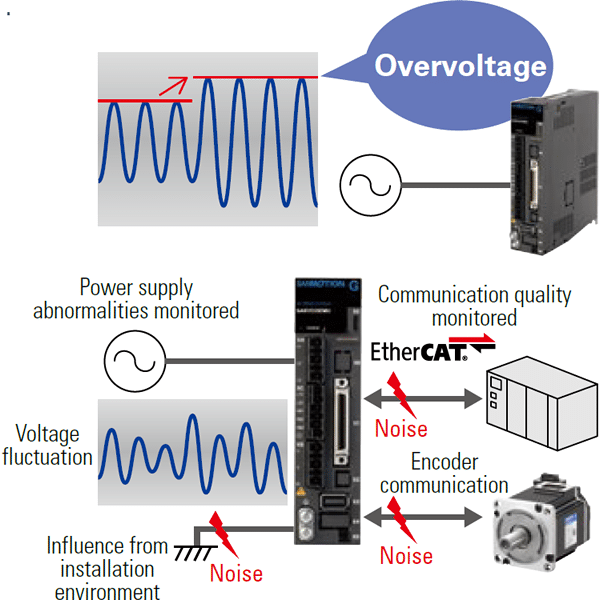

However, uses actual operating conditions—temperature drift, power-quality irregularities, encoder communication noise, brake wear behavior—to forecast when a problem will occur before it disrupts production.

In short:

For servo-driven axes where uptime directly impacts throughput, this shift is meaningful.

A food-production site running large mixers faced exactly this dilemma. When a mixer’s motor or amplifier failed, the line didn’t just pause—batches of in-process material became scrap. Each incident carried real financial impact.

The end user asked the machine builder for a mixer that could support predictive maintenance. The challenge: budgets were tight, and complex external sensor systems would have driven cost and development time too high.

The answer came from the servo platform itself.

By using SANMOTION G servo system, the machine builder tapped into the condition-monitoring features already embedded in the motor, encoder, and amplifier:

Instead of redesigning the machine around add-on IoT hardware, the mixer gained predictive capability simply by specifying a servo system with intelligence already inside.

For the end user, the outcome was practical and immediate:

fewer surprises, fewer stops, and fewer wasted batches.

Whether it’s food processing, packaging, semiconductor handling, or any multi-axis industrial machine, servo-driven equipment is being pushed harder than ever. Higher speeds, faster indexing, more temperature cycling, and more frequent duty cycles all stack up.

Downtime is expensive.

Uncertainty is even more expensive.

Predictive maintenance turns servo performance data into early warnings. A slight rise in inverter temperature, irregular encoder communication, minor shifts in brake-holding behavior—these become signals, not mysteries. Maintenance becomes planned instead of reactive, and production managers gain a more stable, predictable schedule.

For machine builders and engineers aiming to increase both performance and reliability, SANMOTION G brings two advantages together:

A servo system that helps prevent failures is more valuable than one that simply performs well. In modern factories, uptime is the true metric that decides revenue, and predictive maintenance is quickly becoming an expectation rather than an upgrade.

This article is part of SANYO DENKI AMERICA’s motion control engineering knowledge base, sharing practical insights used in real-world servo and motion control applications.

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.