Motion Control Technology by SANYO DENKI AMERICA

SANYO DENKI's Insights on motion control, automation, and precision engineering.

Have you ever wished for a way to achieve precise positioning in your designs without complex control systems? Many engineers and designers face this challenge when developing new equipment. Fortunately, stepper motors offer a compelling solution by enabling high-precision positioning with surprisingly simple control.

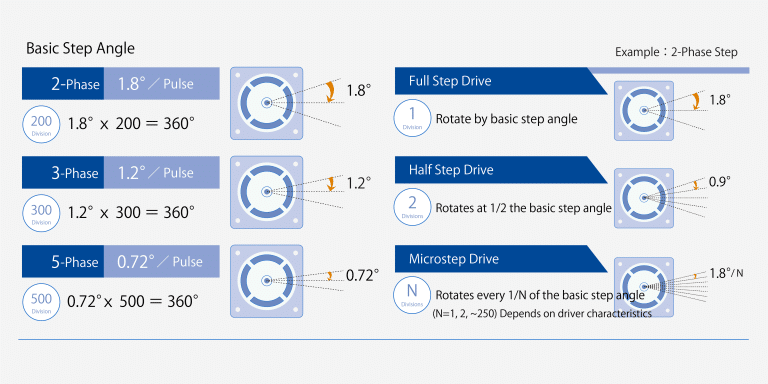

One key reason stepper motors excel in this area is that their rotation speed is directly controlled by the input pulse frequency. Each time a pulse signal is sent, the motor rotates by a fixed angle. By carefully adjusting the frequency of these pulses, you can accurately move an actuator to the desired position, thus achieving high-precision positioning. The step angle itself varies depending on the motor’s number of phases and can be further divided through driver control for even finer movements.

Stepper motors possess a strong stopping force, also known as holding torque. This structural feature, which utilizes magnetism to maintain the motor’s position, makes them ideal for applications requiring precise and stable stops.

Unlike servo motors, which require detectors and feedback loops, stepper motors utilize open-loop control. This simplifies the system design and contributes to cost reduction by eliminating the need for a detector.

Stepper motors provide a straightforward yet effective method for achieving high-precision positioning. Their reliance on pulse frequency for control and inherent holding torque, coupled with the simplicity of open-loop operation, makes them a valuable tool for a wide range of applications, including:

Also, read our blog on Micromachining application with stepper motors:

Master Micromachining: SANYO DENKI Stepper Motor System’s Superior Accuracy and Speed

In conclusion, stepper motors offer a simple yet powerful solution for achieving high-precision positioning in various applications. Their direct control via pulse frequency, strong holding torque, and simplified system design make them an excellent choice for engineers and designers looking to enhance the accuracy and reliability of their equipment.

Stay tuned for more insights and updates on how stepper motors and other motion control technologies can benefit your designs. If you have any questions or need further information, feel free to reach out to our team.