The S100 includes an integrated development tool for batch management of tasks like configuration, programming, screen creation for web visualization, and data tracking in a tree structure.

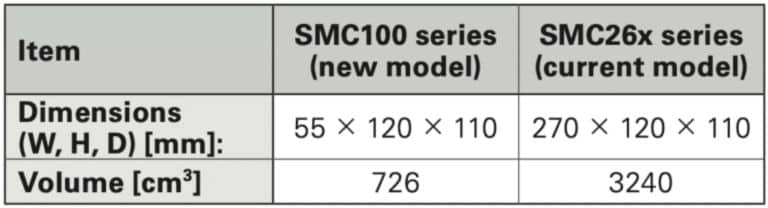

Modern day motion controllers require communication functions to gather and transmit data from production equipment to production management systems. Moreover, to meet customer demands for effectively utilizing space on the production line and achieve a high-mix/low-volume production, compact controllers can free up space in control panels.

To meet such needs, we developed a compact motion controller which features a compact 3-in-1 motion controller to program PLCs, motion control, and robotic functions, as well as enhanced capabilities for communicating with industrial networks.

This post introduces the product features of the SMC100—the newest addition to the SANMOTION C motion controller lineup.

The innovative design of the casing on the S100 resulted in better heat dissipation, which eliminated the need for a cooling fan, further enhancing the reliability of the new model.

The innovative design of the casing on the S100 resulted in better heat dissipation, which eliminated the need for a cooling fan, further enhancing the reliability of the new model.

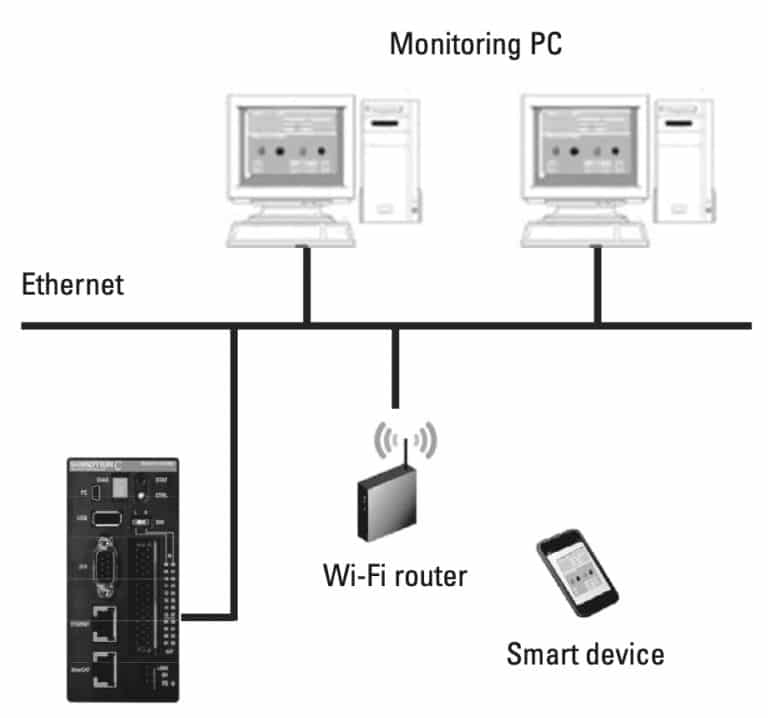

Strengthened Network Functions

Furthermore, with a wireless environment and the web visualization function, operators can view the status of production equipment in real time via a smart device. If a fault occurs, operators will be immediately notified via their smartphone so that equipment downtime can be minimized.

Integrated development software (SANMOTION C Software Tool)

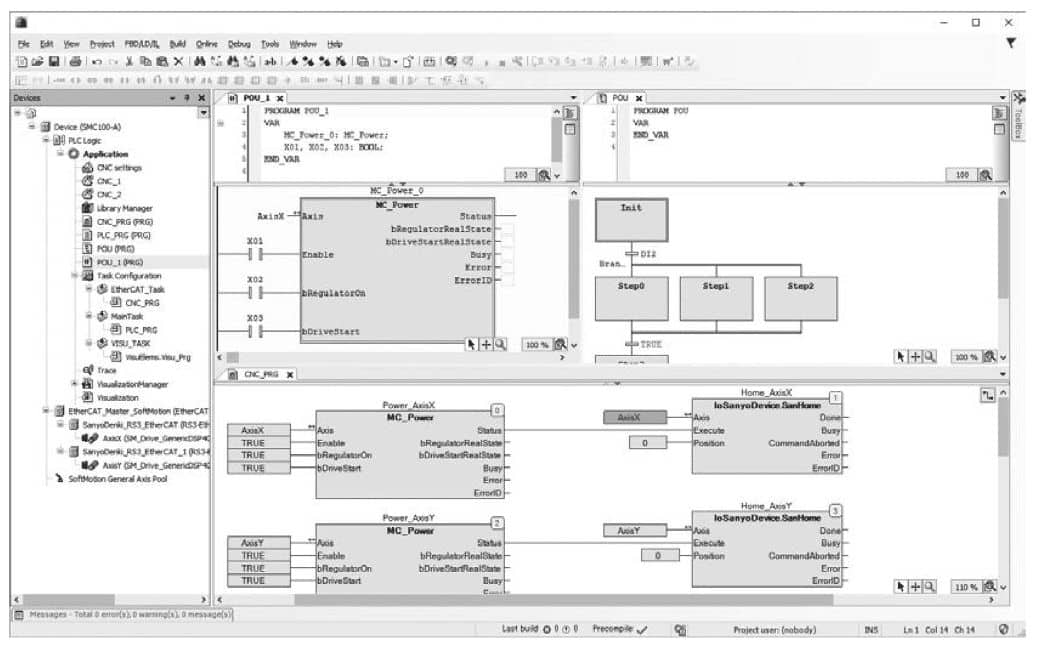

We have developed an integrated development tool for batch management of tasks like configuration, programming, screen creation for web visualization, and data tracking in a tree structure.

This figure shows the configuration screen while configuring SMC100 and fieldbus devices. The layout of this screen enables simple configuration of the parameters for connected devices.

Programming function

The figure below shows an example of a screen for creating application programs. IEC 61131-3-compliant programming languages IL (instruction list), LD (ladder diagram), ST (structured text), SFC (sequential function chart), FBD (function block diagram), and CFC (continuous function chart) are available. Moreover, function blocks for motion control and robotics streamline programming tasks.

CNC editor function

The S100 also has a function to automatically convert CAD data (DXF file) into DIN 660250-compliant G-code. This function automatically generates the G-code control program, reducing the time needed for application development.

Web visualization function

The web visualization function has a drawing tool for designing screens to display controller information on smart devices. There is an alarm display, user management, and various other drawing parts, making it possible to create complex programs and movements in a short time.

The new model helps save space on the production line, enables efficient data transmission between devices, and helps develop production equipment that effectively utilizes production data. We will continue to develop products with features that meet market requirements to help create new value.

Check out the links below to learn more about the new features designed in the S100.