Linear Actuators Total Travel Time Comparison Demo

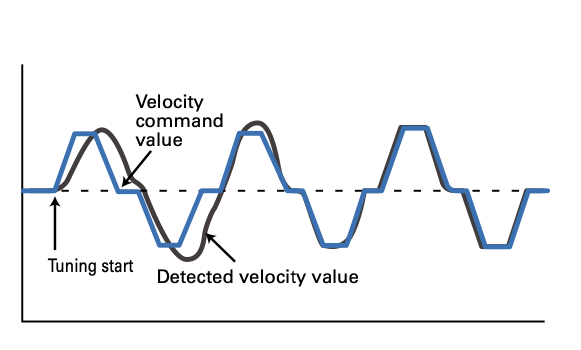

The difference between low and medium rotor inertia in servo motors makes a big difference in velocity! Our booth representatives will demonstrate how to select the correct servo system for your motion profile by matching load inertia to the servo motor’s rotor inertia for the proper ratio.

Pre-assembled High Performance Linear Actuators

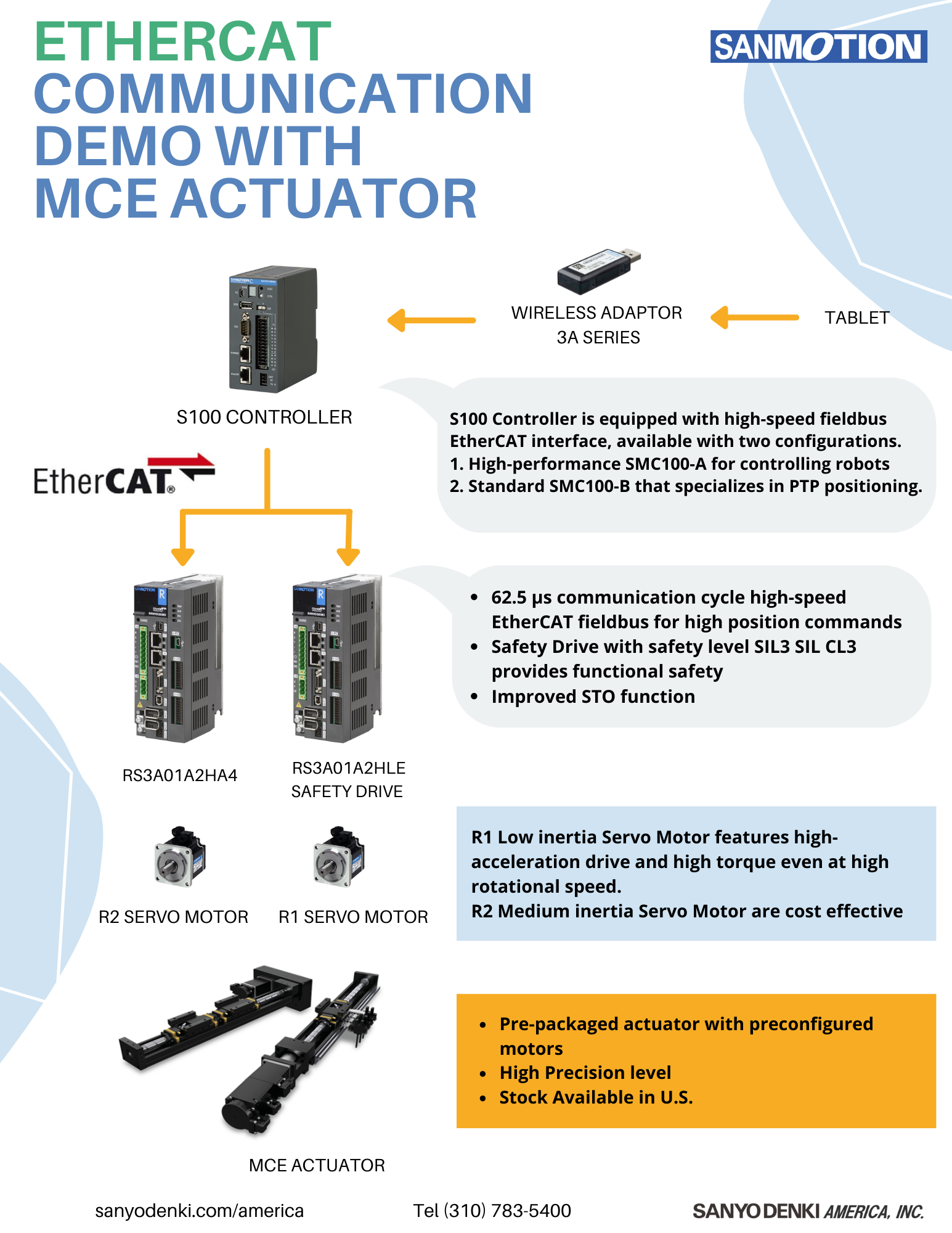

NSK’s MCE linear actuators, integrated with SANYO DENKI motor and NBK Coupling, are pre-tuned to improve takt time and bring optimized performance.

SANYO DENKI and NSK seamlessly integrated our accumulated expertise with ball screws, linear guides and support bearings into a lightweight, compact and highly precise single-axis actuator. The MCE Series is a preassembled, pretested motorized linear actuator. The MCE Linear Actuator is a turnkey solution that offers significant benefits:

- Streamline – consolidating multiple components into a single, compact and customizable part number

- Simplify – reducing design, test and installation time

Support – dedicated collaboration, project management and technical expertise from NSK and Sanyo Denki

A high-gain rubber type coupling from NBK can be used at even higher gain than high-rigidity disk-type couplings enabling the reduction of stabilization time. The vibration absorption reduces the amount of gain tuning and operates at optimal parameters for enhanced productivity.

ATX East - Network Communications Demos

EtherNet I/P Demo

EtherCAT Demo

Profinet Demo

Matching the right actuation to your motion profile and loads is an essential first step for a successful project.

Download sizing software to select the right motion control system for your application.