Motion Control Technology by SANYO DENKI AMERICA

motioncontrol.blog is operated by SANYO DENKI AMERICA and shares motion control engineering insights for industrial applications.

CNC machining keeps raising the bar on precision and throughput. Toolpaths are faster, geometries are more complex, and customers expect flawless surfaces out of the machine. At the center of all of this is the CNC spindle motor—the component that ultimately determines cutting speed, stability, and surface quality.

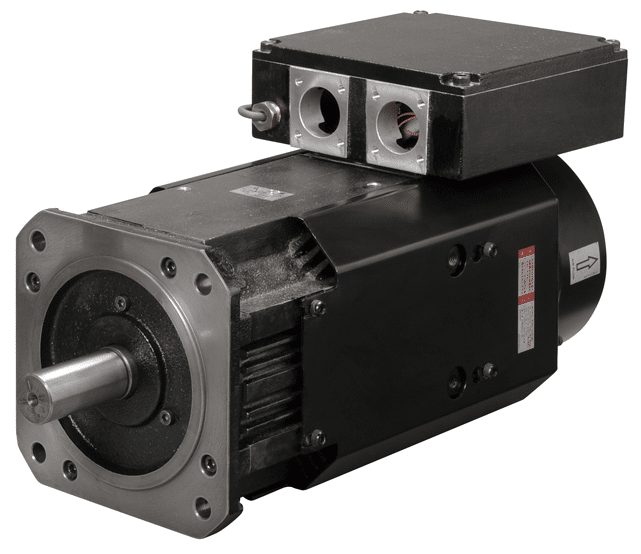

SANMOTION S spindle motors are built for this environment, delivering the speed, control, and rigidity required for next-generation machining.

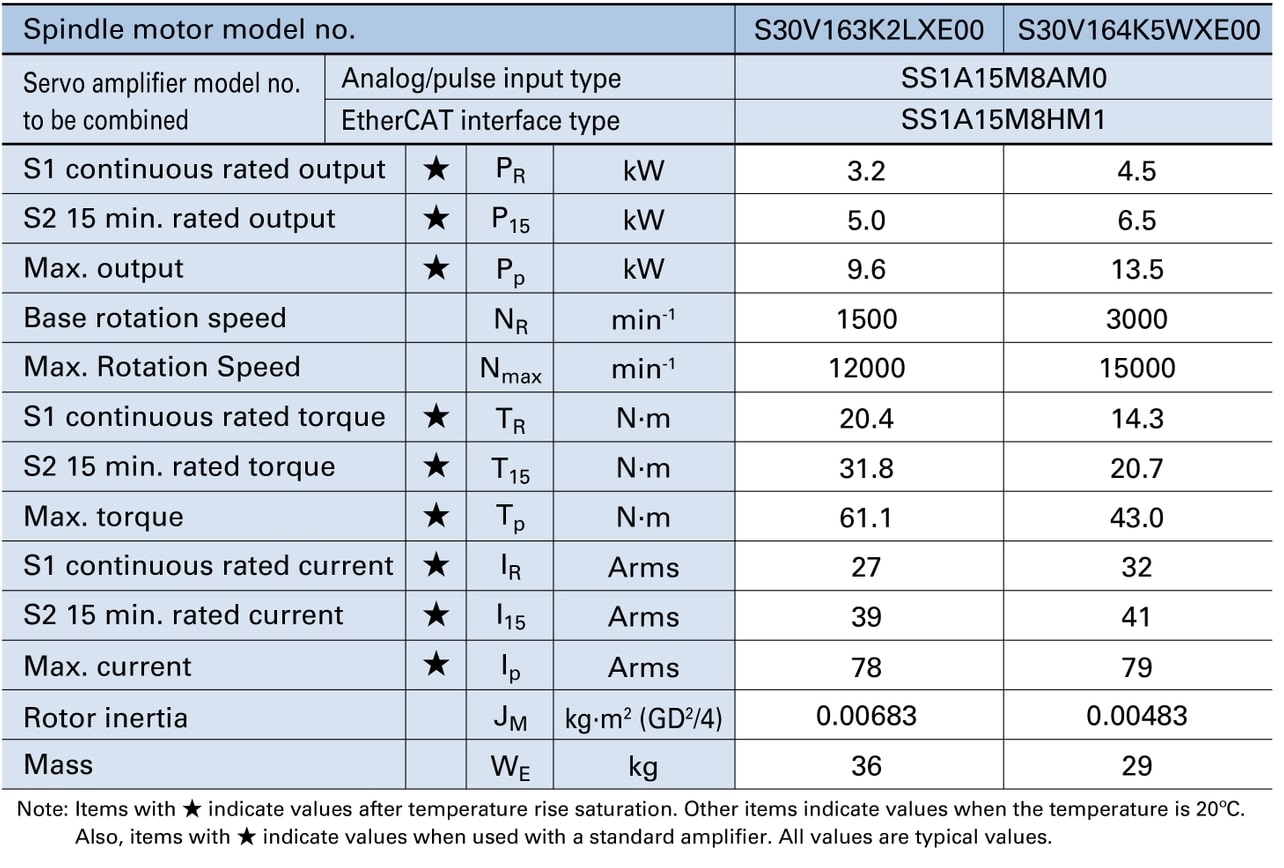

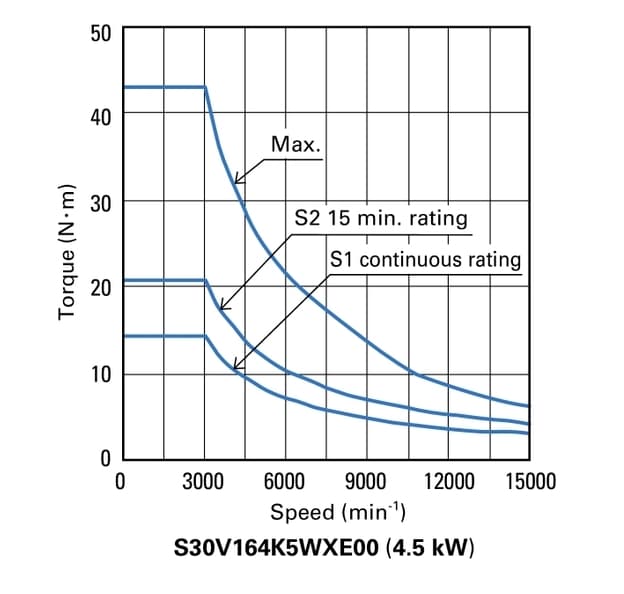

Designed for high-speed machining, the SANMOTION S Series reaches 15,000 RPM in its standard specification, with optional configurations supporting more than 20,000 RPM for ultra-high-speed cutting applications. This gives machine builders a clear path to tailor spindle performance to their cutting needs—whether for high-speed milling, micro-machining, or fine finishing.

Higher rotational velocity improves chip formation, reduces cutting forces, and enhances surface quality, especially when tool geometry relies on stable high-RPM engagement.

Speed Highlight:

20,000+ RPM available → performance aligned with advanced machining demands.

High-speed machining requires a spindle motor that doesn’t lose stability under load. SANMOTION S delivers:

Combined with precise servo control, the spindle maintains predictable cutting behavior even during aggressive tool engagement or rapid toolpath transitions.

Torque Highlight:

Consistent torque = cleaner finishes and stable tool performance at high RPM.

Every CNC machine tool requires a spindle system matched to its size and cutting conditions. If you need different torque curves, unique speed characteristics, or specific acceleration response, we can support you in selecting a SANMOTION S configuration that aligns with your machining goals.

Some applications also benefit from higher rotor inertia for greater stability during heavy cutting or for large-diameter tools. SANMOTION S can be customized to provide the inertia profile your machine requires.

Speed, torque, and inertia are all customizable, creating a spindle system that fits your machining strategy instead of forcing you to work around fixed specifications.

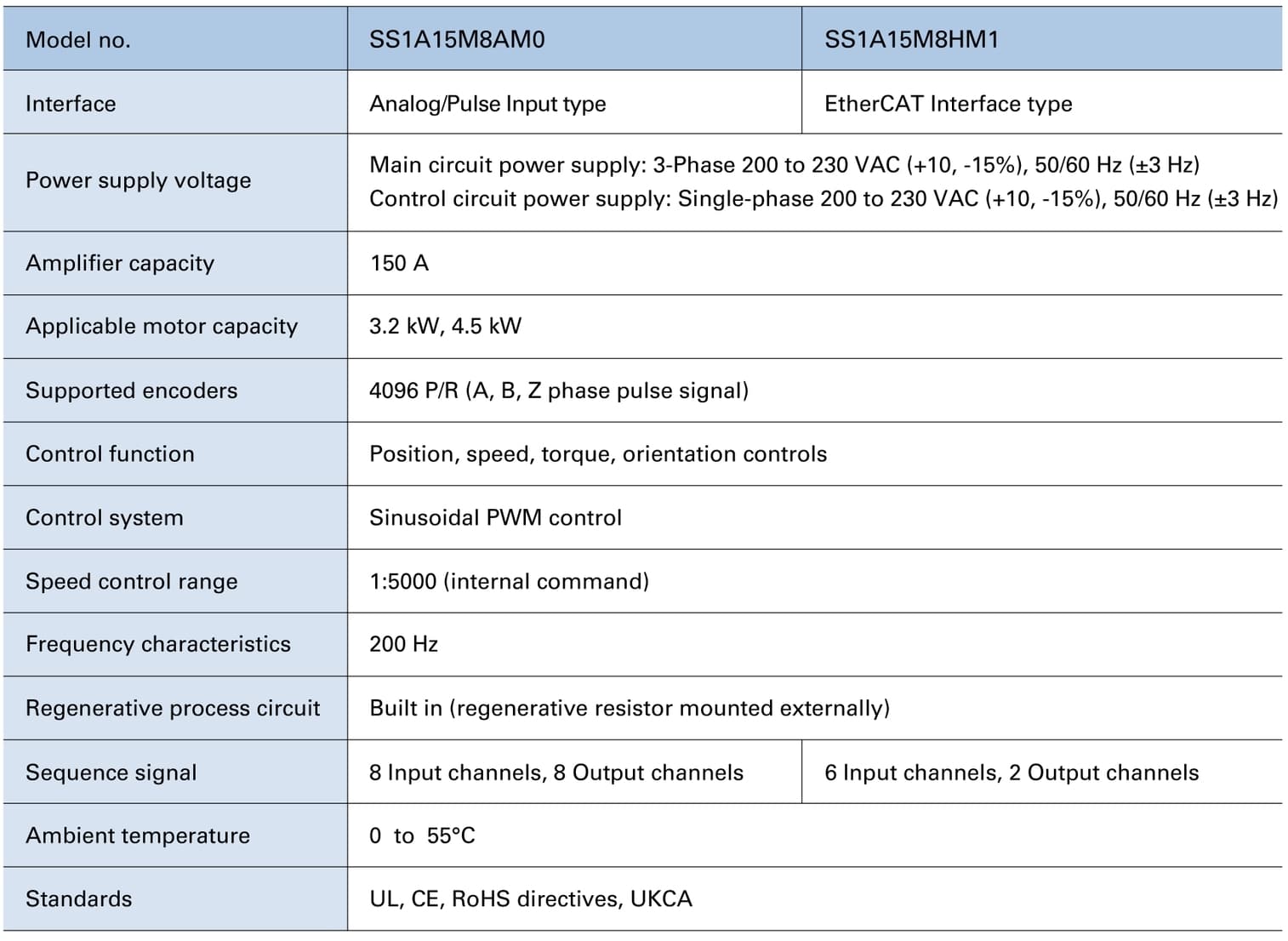

Pair SANMOTION S with its dedicated amplifier to achieve a responsive, high-speed closed-loop control system.

Amplifier + Encoder Synergy

This control platform also supports customized torque, inertia, and speed tuning, helping machine builders achieve exactly the spindle behavior their application requires.

CNC environments rarely slow down—machines run constantly, often unattended. Spindles operating at high RPM need thermal stability and structural rigidity to maintain accuracy.

SANMOTION S supports this with:

This combination delivers fewer dimensional shifts, longer tool life, and confidence during long-duty machining.

High-speed machining depends on a spindle system that combines velocity, stability, and high-resolution feedback. With an option that exceed 20,000 RPM, strong torque characteristics, and absolute encoder support up to 27-bit resolution, SANMOTION S spindle motors give CNC machine tools the performance needed for demanding, precision-driven machining environments.

They’re an ideal match for high-speed milling, machining centers, mold and die applications, micro-machining, and turning or grinding operations where spindle speed, accuracy, and feedback quality define machining success.

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.