Servo Selection with Chip Mounter Example

In this blog post, we’ll explore an application example of chip mounters and discover how SANMOTION Servo and Stepper Motor Systems can contribute to efficiency of the machine.

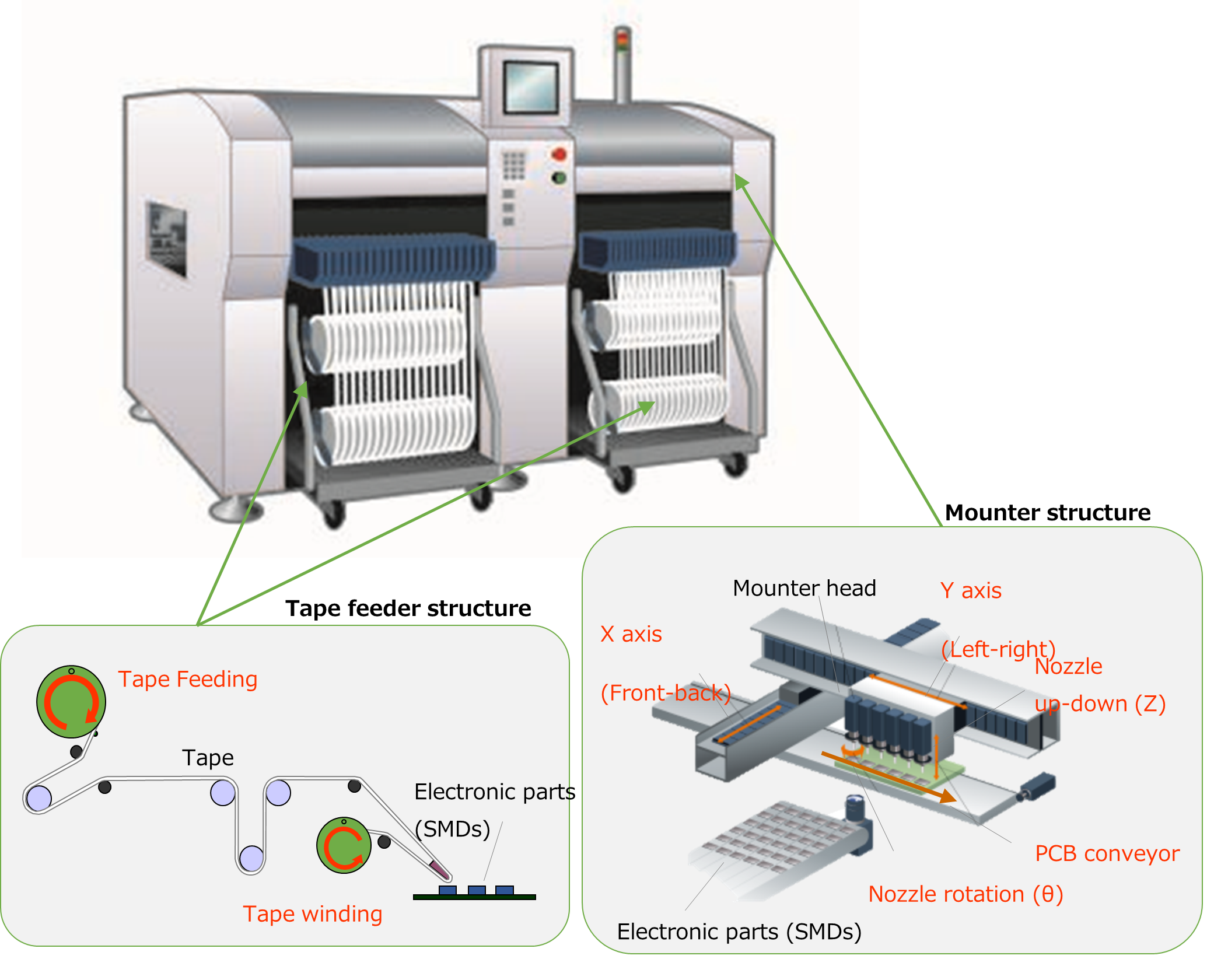

Chip Mounter Structures

Chip mounters are essential tools in the assembly of printed circuit boards (PCBs). These robotic machines accurately place surface-mount devices (SMDs) onto PCBs, ensuring seamless connectivity in modern electronic devices. To achieve this precision, a complex system of components is employed, and the choice of motors plays a crucial role.

SANYO DENKI's Motor Selections

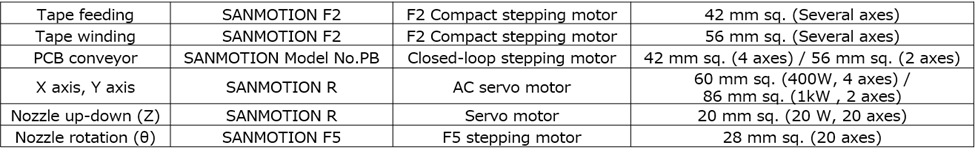

- Tape Feeder and Tape Winding:

The tape feeder is responsible for supplying chips to the mounter. SANYO DENKI recommends the use of the SANMOTION F2 compact stepping motor in two sizes – 42mm sq. for Tape Feeding and 56mm sq. for Tape winding. The thin profile of these motors allows more feeders into a machine, contributing to increased productivity. Also, the compact design doesn’t compromise on torque, making it an ideal choice for efficient chip feeding.

Compact Servo Motor is also available for synchronization of feeder and winding.

- PCB Conveyor:

In the PCB conveyor system, The Model No. PB, a Closed-Loop Stepping Motor, is used in 42mm sq. (4 axes) and 56mm sq. (2 axes) configurations. Feedback and closed-loop control are available with PB model stepper motors. The high torque that’s achieved via the closed-loop control manages the large inertial load of the conveyer’s belt and pulleys for stable starts and stops during quick motion.

- X-Y Robot:

The X-Y robot is responsible for the movement of the mounter in the X and Y directions. For this application, SANYO DENKI suggests the use of SANMOTION G AC Servo Motors in two sizes: 60mm sq. (400W, 4 axes) and 86mm sq. (1kW, 2 axes). These motors offer unparalleled performance with cycle time and accuracy, essential for precise placement of components.

- Mounter Head:

The mounter head is at the heart of the chip mounter, picking electronic parts from the feeder and placing them onto the PCB. SANYO DENKI recommends SANMOTION F5 Stepper Motors in a compact 28mm sq. size with 20 axes. This choice guarantees high accuracy and repeatability, reduced vibration, and improved acceleration performance, enhancing the overall chip placement process.

- Nozzle Axis (Z):

On the Nozzle Axis (Z) for precise up and down motion, the 20mm sq. AC Servo Motor + Driver stands out, with its compact, lightweight design, high torque, and industry-leading acceleration.

- Nozzle Axis (θ):

The Nozzle Axis (θ) benefits from SANMOTION F5 Stepper Motor + Driver, a 5-phase micro-step stepper system that offers higher accuracy, reduced vibration, and improved acceleration performance compared to 2-phase systems.

Wide Variety of Products for Requirement of Each Axes

It is essential to select the most suitable or appropriate motors for each axis, based on the specific requirements. For example, some axes may need higher speed, torque, or accuracy than others, and some motors may consume more power or generate more heat than others. Therefore, it is important to consider these factors when selecting the motors for each axis, and avoid choosing over-specified motors that can increase the energy and cost.

With a diverse range of motor types, including servo, stepper, and closed-loop stepper motors, you can select the perfect match for each specific axes, ensuring precision.

Advantage of of Choosing SANMOTION Servo Systems

- High Precision and Reliability: SANYO DENKI’s motors are renowned for their precision and reliability, ensuring that your equipment performs consistently at its best.

- Variety of Stepping Motors: SANYO DENKI offers 2-, 3-, and 5-phase stepping motors, providing flexibility in matching motors to equipment requirements.

- Closed-Loop PB Motors: The closed-loop feature of PB motors eliminates step-out caused by sudden speed changes and overloads, enhancing device reliability.

- Enhanced Productivity: High-speed and accurate positioning with servo motors shorten machine cycle times, resulting in higher productivity.

- Space Efficiency: The thin stepping motor and compact servo motor designs enable engineers to load more feeders, thus maximizing productivity and machine space efficiency.

- Single Sourcing for Better Maintainability: By sourcing all their motor needs from SANYO DENKI, engineers can improve equipment maintainability and reduce compatibility issues.

Want to learn more about our motor types and features? Visit our core catalog, or contact us. We are happy to assist you on selecting the right motor.

Request a Consultation

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.