Enhancing Performance through Optimal Motor Selection

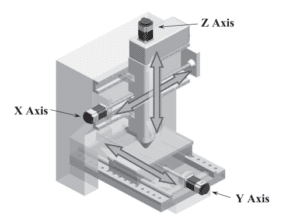

When selecting AC servo motors in your equipment, it is important to consider various factors such as acceleration/deceleration performance for each axis (XYZ), contouring control, stabilization, cycle time, space occupancy, and mass. Additionally, each application has its own specific requirements, customer preferences, and unique demands for different axes within the same device.

While our versatile R2-Series motor covers a wide range of elements, it’s crucial to avoid pushing it to its limits. In some cases, when the motor is operating at its maximum capacity, certain axes may become a bottleneck, negatively affecting the overall device performance. Therefore, it is recommended to choose products that are well-suited for the specific application and consider the elements that may restrict performance. By doing so, we can greatly enhance motion characteristics and improve the overall cycle time of the device.

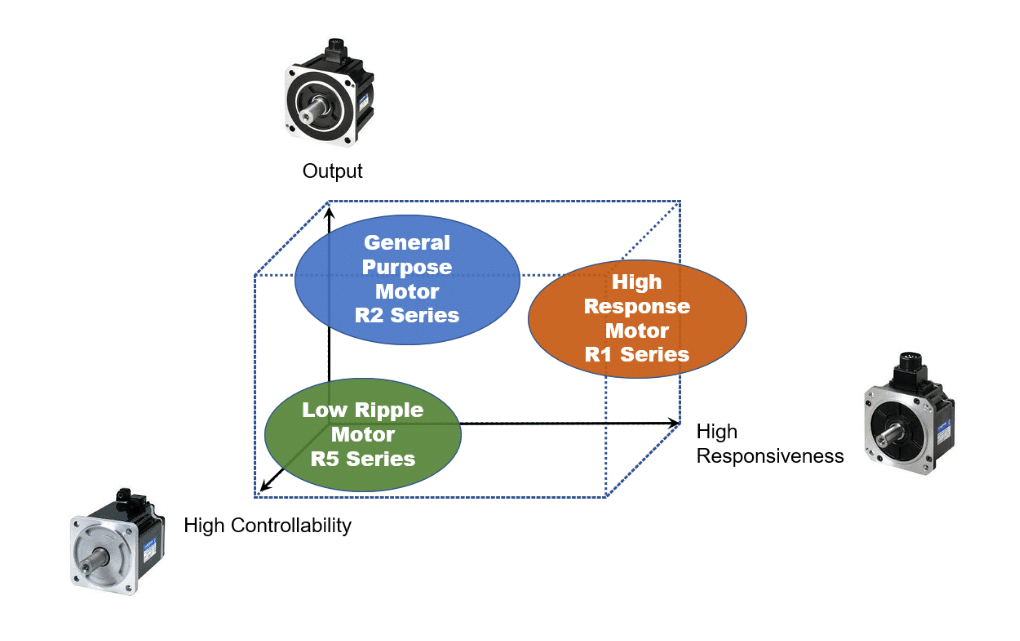

The three-dimensional conceptual map shown above represents the R Series product lineup relative to different performance requirements. For high torque, high-efficiency general purpose applications, the R2 Series model is best suited. The R5 Series specializes in low-speed precision feeding and positioning, and the R1 Series primarily offers high response and high acceleration/deceleration.

The R Series Motor Characteristics and Applications

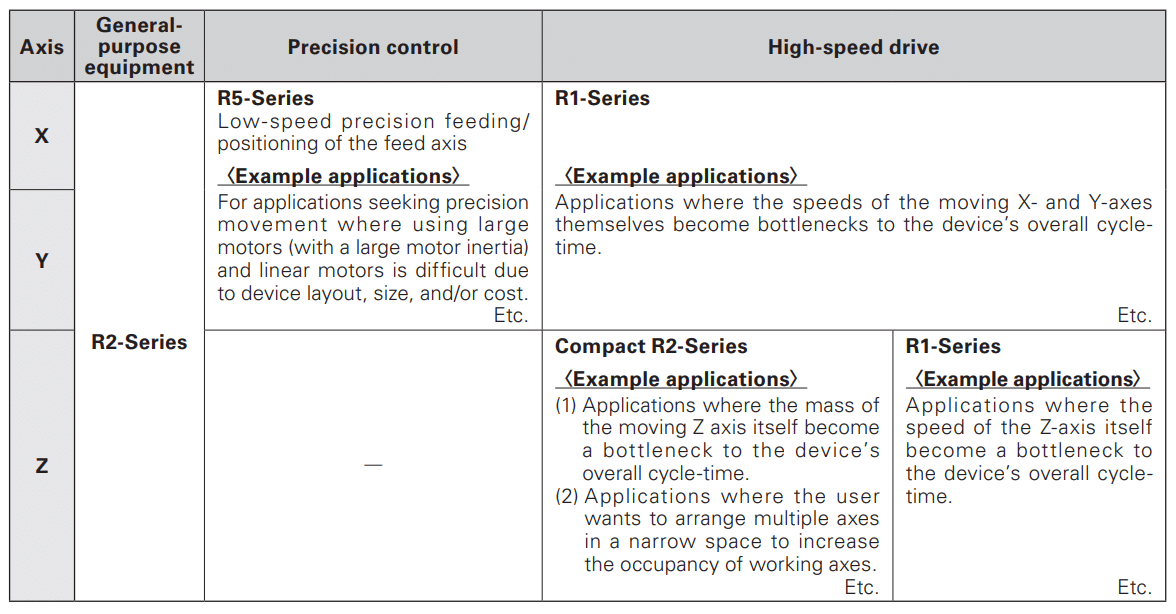

To achieve balanced movement across multiple axes, a potential scenario, as illustrated in the Table above, could involve the utilization of different motor series. Here’s an overview of the suggested motor choices for specific requirements:

R5-Series: The R5-Series is recommended for axes that demand precise control. With its high-performance capabilities, this series ensures accurate positioning and reliable operation.

R2-Series: If the emphasis is on weight reduction and a smaller footprint, the compact R2-Series is a suitable choice. It offers a balance between size and performance, making it ideal for applications where space optimization is crucial.

R1-Series: For high acceleration and rapid response applications, the R1-Series is the preferred option. This series excels in delivering fast and dynamic motion with exceptional responsiveness.

By strategically selecting the appropriate motor series based on specific axis requirements, you can achieve optimized performance and fulfill the unique needs of each application.

SANMOTION R Motor Lineup

R1 High Response Motor

R1 High Response Motor

This motor offers both small motor inertia and improved peak torque which drastically reduces the time required to accelerate/decelerate machines under load. They are ideal for use in equipment such as robots, injection molding machines, and general industrial machinery.

R2 General Purpose Motor

R2 General Purpose Motor

The low cogging torque delivers smooth rotation that is ideal for high precision processes and vibration-sensitive conveyor applications. They are ideal for use in equipment such as robots, injection molding machines, and general industrial machinery.

R5 Low Ripple Motor The R5 Servo motor is suitable for high-precision locating and smooth precision feeding. This makes them ideal for applications such as machine tool feed shafts which are required to have high precision and high-quality machining ability. This AC servo motor offers an alternative to the commonly used high inertia motor, enabling significant machine downsizing and cost reduction.

R5 Low Ripple Motor The R5 Servo motor is suitable for high-precision locating and smooth precision feeding. This makes them ideal for applications such as machine tool feed shafts which are required to have high precision and high-quality machining ability. This AC servo motor offers an alternative to the commonly used high inertia motor, enabling significant machine downsizing and cost reduction.

Please note that the actual selection of motor series may depend on various factors, including the specific application, performance goals, and other project-specific considerations. Consulting with SANYO DENKI AMERICA or referring to our official documentation can provide more precise guidance tailored to your requirements.

Request a Consultation

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.