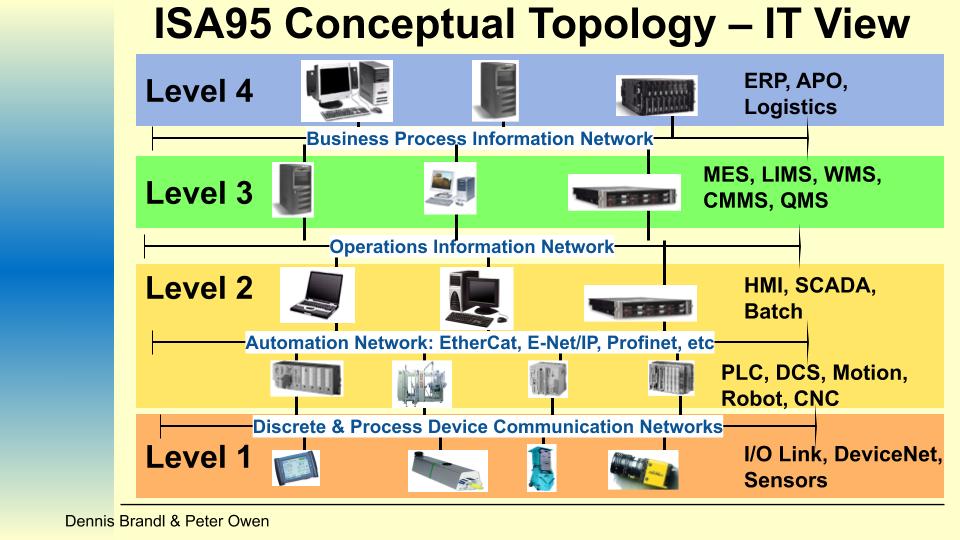

The ISA-95 Framework from Automation, IT, and Management perspectives

ISA-95 Levels Described

ISA-95 is the international standard for the integration of enterprise and control systems. Designing organizational data communication using the ISA-95 standard requires various models and terminology. ISA-95 models the layers of technology and business processes for manufacturing as levels. The levels are described as:

- Level 0: Defines the actual physical processes.

- Level 1: Defines the activities involved in sensing and manipulating the physical processes.

- Level 2: Defines the activities of monitoring and controlling the physical processes.

- Level 3: Defines the activities of workflow to produce the desired end products.

- Level 4: Defines the business-related activities needed to manage a manufacturing operation.

With the description of the ISA-95 standard, organizations can apply the functions of the levels to their departmental goals and communication models.

ISA-95 from the viewpoint of the Automation Pyramid

The image on the left presents the automation pyramid model as an infographic for which automation controls and devices are used on which level for communication in the ISA-95 framework. SANMOTION servo controllers and amplifiers are designed with embedded protocols to communicate the motion control happening on Levels 0-2 further up the pyramid to improve production insights.

ISA-95 Model from IT's Perspective

The common feature of the different models is the accession of the levels from the physical production process and the integration of specific automation techniques in every level generally becoming more business-centered as they go up and production-centered as they go down. Because of the different models and conflicting language between IT and OT (Operations Technology), a collaborative meeting with each departments’ input is encouraged to agree upon a common language across an architectural layout.

The infographic above is an example of an ISA-95 hierarchy from IT’s perspective of the devices and software that drive the systems. From IT’s perspective, OT is separated from IT. For example, the SANMOTION C controller on Level 2 would drive a servo motor on Level 1 with a fieldbus and communicate its position over Ethernet TCP/IP using a protocol like Modbus TCP to an HMI and/or SCADA. The information is integrated with Level 3 using MES and/or OPC-UA architecture where the data can be routed to Level 4 for the ERP software. This type of information system is designed to integrate production data with business software to visualize and measure a company’s KPIs (Key Performance Indicators).

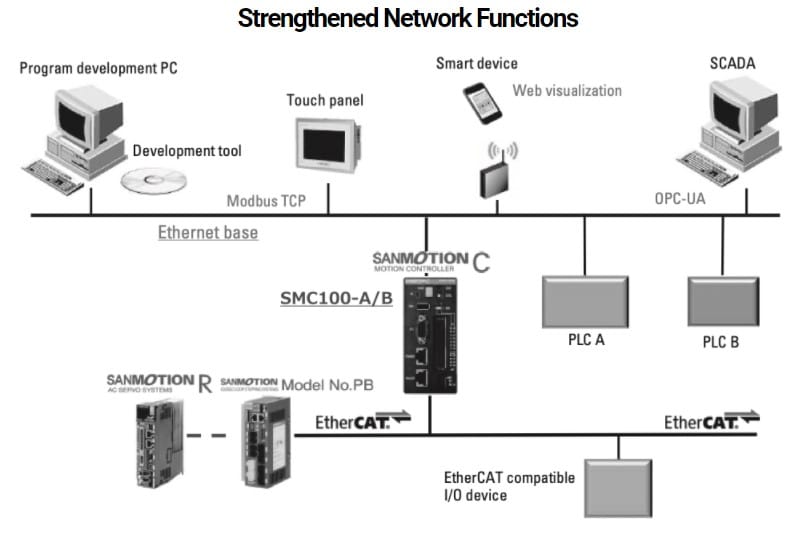

Using ISA-95 for Enterprise Production Management with MES

The infographic on the right is an example of an ISA-95 hierarchy from an MES (Management Execution System) perspective.

Each of these infographics: the automation pyramid, the IT topology, and the MES architecture represent how data communication is organized using different models according to the ISA-95 standard for integrating industrial control systems with enterprise software.

Industrial network protocols are embedded to integrate SANMOTION servo systems according to an ISA-95 framework.

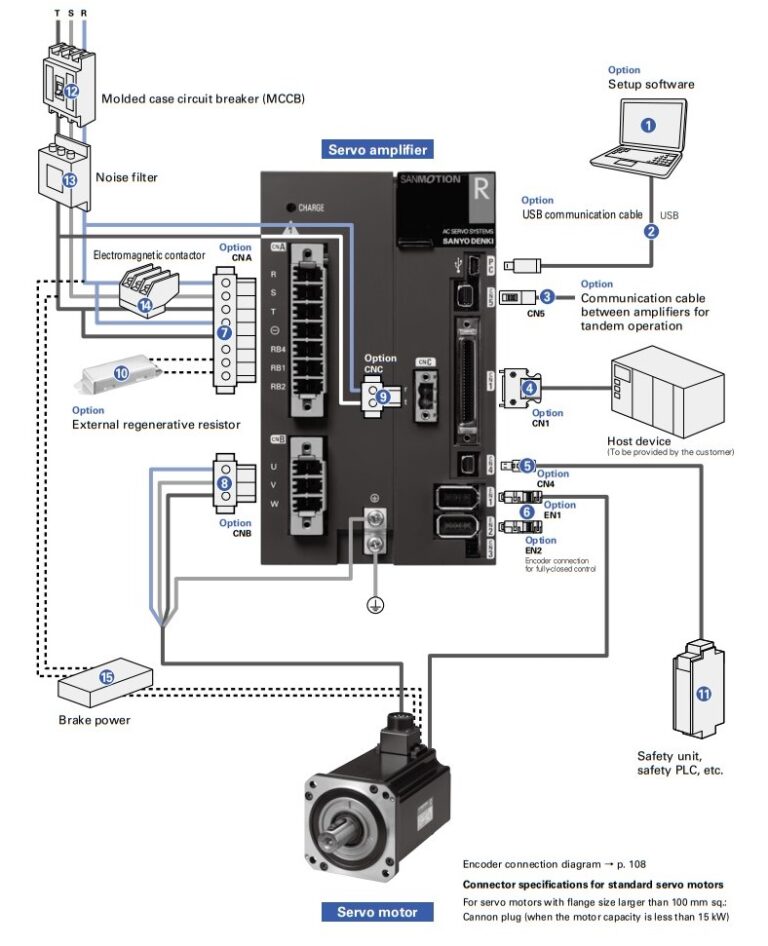

Servo Amplifier Communication

The image above is the system configuration for a SANMOTION R Series amplifier. The servo amplifier is a device that would be located on Level 1 of the ISA-95 automation pyramid with other intelligent devices.

By leveraging the strengths of high-speed communication, we have maximized servo performance and enabled smooth motion, thus shortening the minimum communication cycle to 62.5 μs on the newest models. (During speed control and torque control mode; 125 μs for others.) SANMOTION amplifiers are designed with EtherCAT to synchronize multiple servo axes and other fieldbus protocols (Ethernet/IP, ProfiNET) for remote I/O. While the high-speed fieldbus protocols subdivide commands for smoother operation of devices, it also provides high-speed communication between the devices and sensors on Level 1 and the controls on Level 2. Paired together with high-performance motion controllers, SANMOTION provides extremely versatile and accurate systems to include in a wide array of automation applications. Contact your regional applications expert to match your next servo systems to the ISA-95 global communication standard.

Servo Efficiency with Integrated Communication

An application example is the monitoring of your motion control systems for energy efficiency. Incorporating new-generation power devices, the SANMOTION R Series 3E servo system decreases electric power losses by up to 10%. The R3E model has up to 10% lower standby power consumption as it limits unnecessary energy expenditure by controlling the fan speed according to the internal temperature of the servo amplifier. Energy savings add up in industrial processes that have long periods of time in between motor firings, such as injection molding; the less energy consumed during the machine’s idle time the better, especially for multi-axis systems that are synchronized using the communication port (CN5). The monitoring data is shared with the host controller via the CN1 port. The SANMOTION C Series controllers are designed with monitoring software and communication ports included on the hardware.

Motion Control Integration

Supervisory Level Communication

The software found on the 3rd and 4th levels or the management levels of the ISA-95 MES model can be integrated with the SANMOTION C Series controllers and is accessed via an Ethernet port from a web browser on a PC or smart device. The computers monitoring the controller are located behind firewalls on the production management level located between the enterprise level (Level 4) and the control level (Level 2). The network diagram above maps the components with the web visualization function relative to other supervisory hardware. The web visualization function has a drawing tool for designing screens to display controller information on smart devices. There is an alarm display, user management, and various other drawing parts, making it possible to create complex programs and movements in a short time.