In today’s competitive landscape, the ability to achieve ever-increasing miniaturization and precision in semiconductor and medical equipment manufacturing is paramount. This relentless pursuit of advancement hinges on superior stepper motion control systems for the delicate machinery employed in micromachining processes. SANYO DENKI’s latest advancements in stepper motor and motion control technology directly address these challenges by delivering superior accuracy and speed, empowering machine builders to achieve groundbreaking results.

This analysis explores the advanced capabilities of SANYO DENKI’s F series stepper motor systems, specifically designed to excel in the demanding environment of micromachining applications. We’ll investigate how these advanced drivers elevate performance and efficiency, ultimately propelling manufacturing operations to the forefront of technological innovation.

The Growing Significance of Micromachining

Micromachining has become an indispensable technology in both semiconductor and medical equipment industries. This revolutionary technique enables the creation of incredibly intricate features on a microscopic scale, pushing the boundaries of what’s possible.

- Semiconductors: Micromachining fuels Moore’s Law by enabling the continuous shrinking of transistors, leading to more powerful and compact devices. It also facilitates the creation of microfluidic channels and MEMS (Microelectromechanical Systems).

- Medical Equipment: Micromachining allows for the development of miniaturized implants, intricate microfluidic devices for drug delivery and diagnostics, and delicate surgical instruments for minimally invasive procedures.

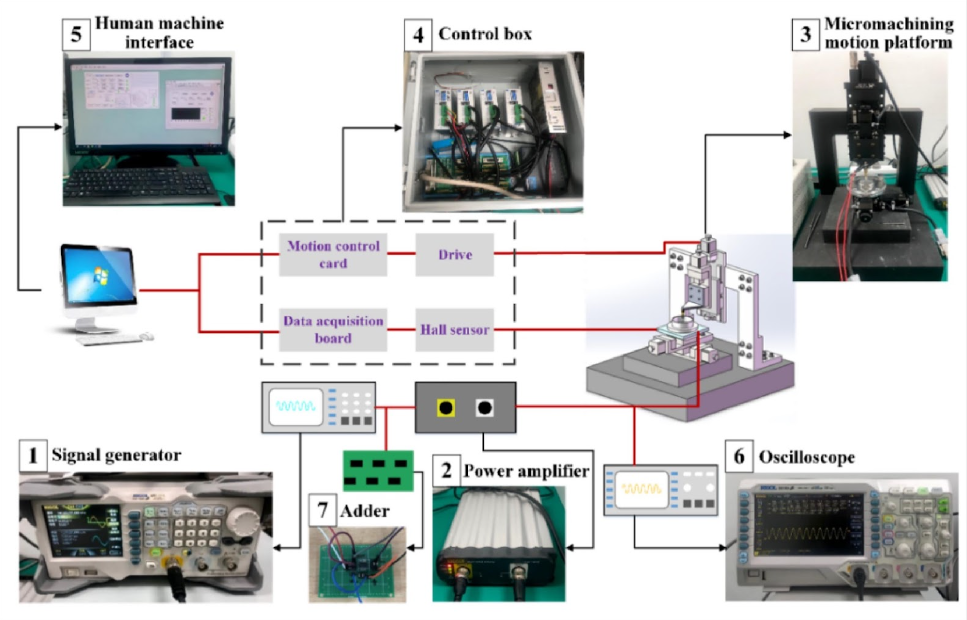

The high precision of micromachining unlocks the creation of complex features that would be impossible with traditional machining techniques. This translates to significant advancements in both industries. An example of how intricate a stepper motor can be to the success of a micromachining process was published in Science Direct: “Electrochemical micromachining on nickel and nickel-based superalloys with two-tone sinusoidal signal”.

Challenges of Automating Micromachining

While micromachining offers immense potential, automating these processes presents a distinct set of challenges:

- Microscopic Forces and Materials: Precise control over forces and vibrations is crucial to avoid damaging delicate workpieces. Traditional sensors might be too bulky or insensitive.

- Tool Wear and Breakage: Microscopic tools are prone to wear and breakage. Automated systems need to detect and compensate for tool degradation.

- Process Monitoring and Adjustments: Direct monitoring can be difficult due to the small scale. Automated systems rely on indirect sensors and real-time data analysis.

- Complexities of Microfluidic Systems: Automating the design and fabrication of intricate microfluidic channels requires sophisticated software and control systems.

- High Initial Investment: Developing and implementing a fully automated micromachining system can be expensive.

SANYO DENKI's F Series Stepper Motor Systems: Mastering the Challenges

SANYO DENKI’s F series stepper motor systems address the unique demands of micromachining applications. These innovative stepper motors and drivers deliver superior accuracy, speed, and efficiency:

- Precise Positioning: The F series utilizes high-precision stepper motors for exceptional control in positioning the cutting tool.

- Reduced Vibrations: Advanced stepper motor control algorithms minimize vibrations during operation, protecting delicate workpieces.

- Real-Time Monitoring: Compatibility with various sensors allows for real-time monitoring of factors like tool wear and vibration levels.

- High-Speed Operation: The F series delivers high stepper motor speeds while maintaining exceptional precision, translating to faster processing times.

New F Series Stepper Driver Models

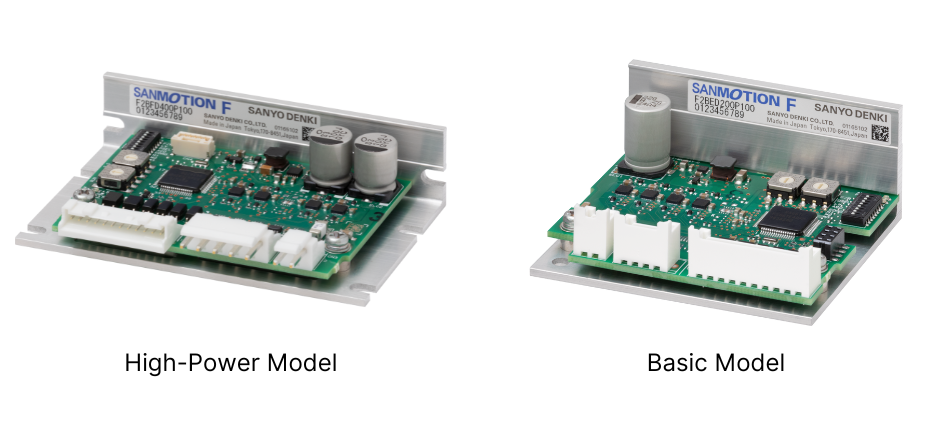

SANYO DENKI’s F series stepper motor systems come in two exciting new models:

High-Power Model: Designed for top-tier performance, this model boasts a compact design, superior performance with high torque output at high speeds, advanced functionality with PC-based control and preventive maintenance features, and enhanced communication capabilities.

Basic Model: This model offers seamless integration with existing setups, delivering a performance boost with increased torque and reduced speed variations, all within a space-saving design.

Choosing the Right Model

The choice between the high-power and basic models depends on your specific micromachining requirements. If maximizing performance and pushing boundaries are your priorities, the high-power model is ideal. However, if seamless integration and a performance boost are your main concerns, the basic model offers a compelling upgrade path.

By understanding the strengths of each model, you can select the F series stepper driver that perfectly aligns with your micromachining goals, empowering you to achieve unparalleled results.

Request A Consultation

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.