In today’s world, manufacturers are under increasing pressure to minimize their environmental impact while maintaining productivity and efficiency. Our whitepaper: “Building a Low-Carbon Society: Energy- and resource-saving initiatives” explores a new generation of industrial automation technology that achieves both. This blog post dives into the design features of SANYO DENKI’s SANMOTION G servo motor and amplifier, showcasing how they contribute to a greener future for manufacturers through a combination of cutting-edge engineering and environmental responsibility.

Designed With Your Environmental Goals In Mind: SANMOTION G Servo System

The design of the SANMOTION G servo motor and amplifier showcases a commitment to environmental responsibility. These products target sustainability throughout their lifecycle, demonstrably reducing environmental impact.

A core principle is energy efficiency. The servo motor achieves this through a combination of innovative design and material selection. By optimizing the electromagnetic field and using low-loss materials, power loss is minimized, leading to up to 9% higher efficiency. Additionally, the servo amplifier maximizes output current by up to 5% using a power semiconductor device with low heat generation. And lower-consumption components are used, resulting in a total power reduction of 22%.

The concept of resource conservation is also central to the design. The servo motor is demonstrably lighter and more compact than previous models, achieving the same performance with less material. Over and above that, batteryless encoders reduce industrial waste associated with battery backup and lower product maintenance costs for manufacturers.

Beyond efficiency and resource reduction, the focus extends to smart energy management. The servo amplifier features built-in power consumption monitoring by calculating the data collected from sensors, enabling manufacturers to identify areas for overall power reduction associated with their machines and optimize electricity use throughout their factories.

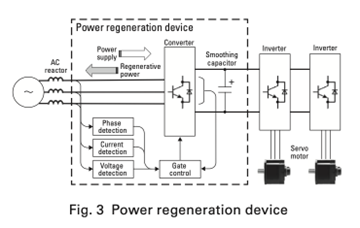

Finally, the system incorporates regenerative power capabilities. The power regeneration device captures the energy typically wasted during deceleration and converts it back into usable electricity. This innovation minimizes environmental impact by reducing overall energy consumption and maximizing resource utilization.

Finally, the system incorporates regenerative power capabilities. The power regeneration device captures the energy typically wasted during deceleration and converts it back into usable electricity. This innovation minimizes environmental impact by reducing overall energy consumption and maximizing resource utilization.

To further learn how each of these product design features were developed, download our whitepaper: “Building a Low-Carbon Society: Energy- and resource-saving initiatives” from below.

Environmental Benefits of the SANMOTION G Servo System in Machine Building

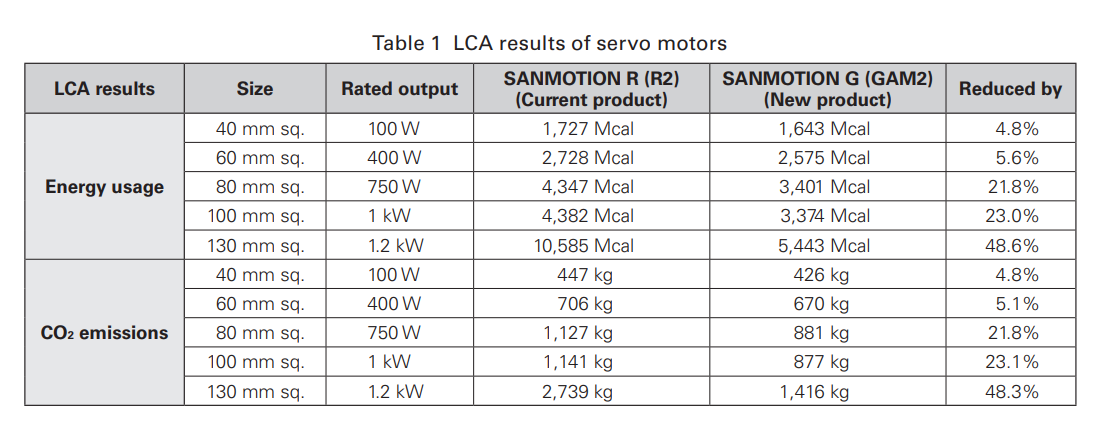

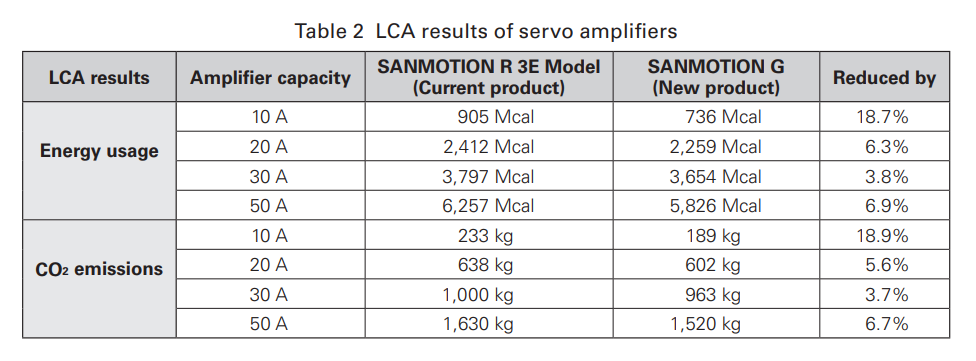

- Reduced CO2 Emissions: The SANMOTION G series products demonstrably cut CO2 emissions through a lifecycle assessment (LCA) by up to 48.6% for servo motors and 18.9% for servo amplifiers compared to previous models.

This translates to a greener supply chain and potential cost savings through carbon credits or environmental regulations.

- Energy Efficiency: These products achieve significant energy efficiency improvements. The servo motor reduces power loss and boasts up to 9% higher efficiency. The servo amplifier utilizes lower consumption components and achieves a 22% total power reduction. This translates to direct cost savings on electricity bills for your business.

- Resource Conservation: The SANMOTION G servo motor is smaller and lighter while maintaining performance. This translates to less material used in manufacturing, reducing environmental impact and potentially lowering your overall product costs.

- Effective Power Management: The SANMOTION G servo amplifier features power consumption monitoring, allowing you to optimize electricity use across your factory. This can identify areas for overall power reduction and cost savings.

- Regenerative Power Utilization: The power regeneration device captures energy typically wasted during deceleration and converts it back into usable electricity. This reduces overall energy consumption and electricity costs, while minimizing environmental impact.

By implementing the SANMOTION G servo system, you’re not just getting powerful and efficient motion control, you’re investing in a solution that reduces costs and helps you achieve your environmental goals.

Request A Consultation

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.