Motion Control Technology by SANYO DENKI AMERICA

SANYO DENKI's Insights on motion control, automation, and precision engineering.

Industry 4.0 is the term for the fourth industrial revolution, which involves the integration of digital technologies, automation, and data exchange in manufacturing systems. One of the key aspects of Industry 4.0 is real-time monitoring, which allows manufacturers to track production status, optimize performance, and prevent errors. SANMOTION motion controllers are essential devices for real-time monitoring, as they provide precise control and feedback of motion-related processes in production lines. In this post, we will explain how SANMOTION motion controllers enable real-time monitoring for Industry 4.0.

SANMOTION motion controllers use feedback sensors such as batteryless encoders, resolvers, or linear scales to measure the position, velocity, and acceleration of moving components. These sensors send real-time feedback to the motion controller, which adjusts the control signals accordingly. This ensures accurate and consistent motion profiles for the production process.

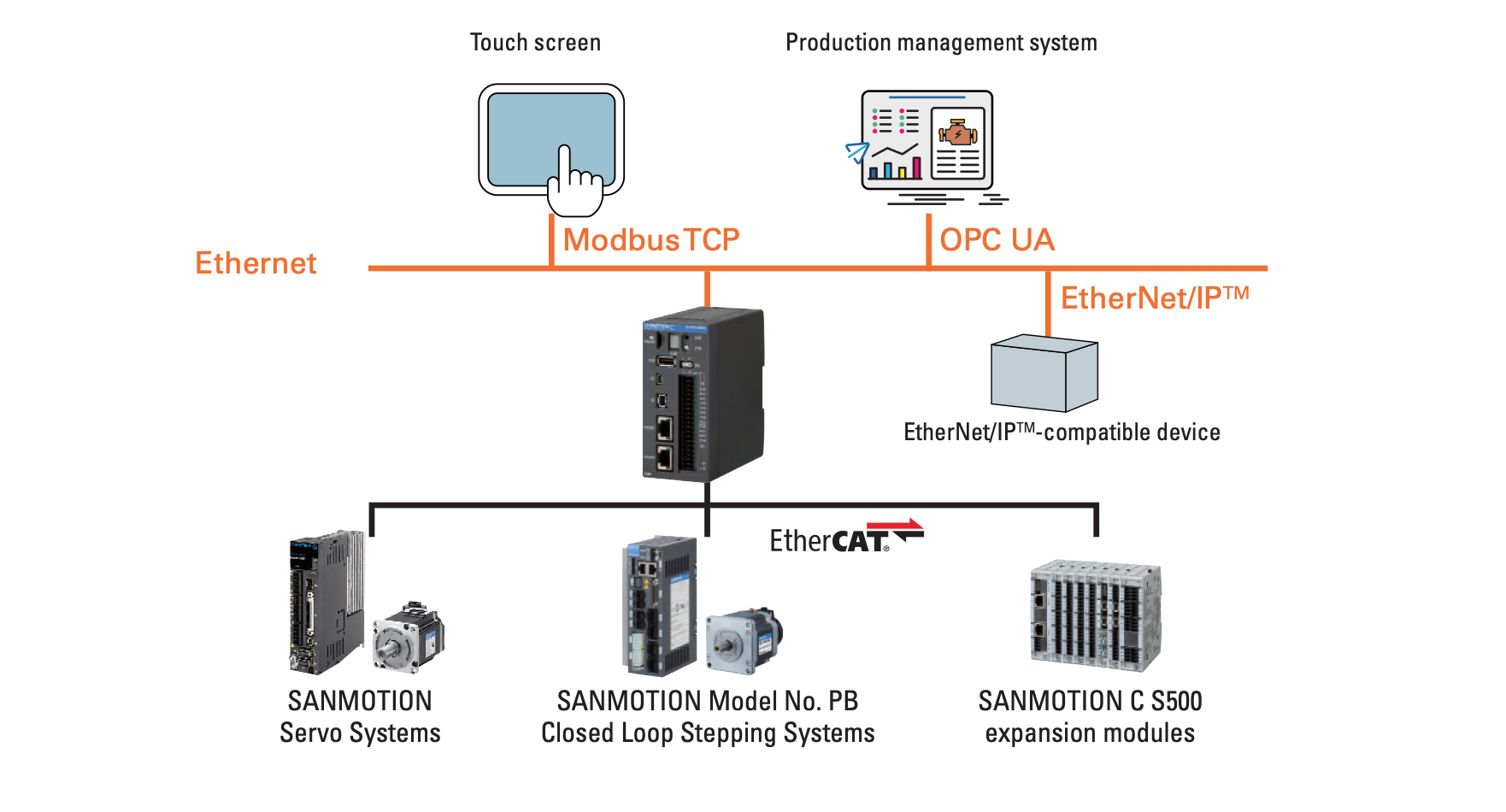

SANMOTION motion controllers also support communication protocols like EtherCAT and Modbus TCP/IP, which allow them to exchange data with other components of the production system. This enables coordinated operation and real-time sharing of production status information.

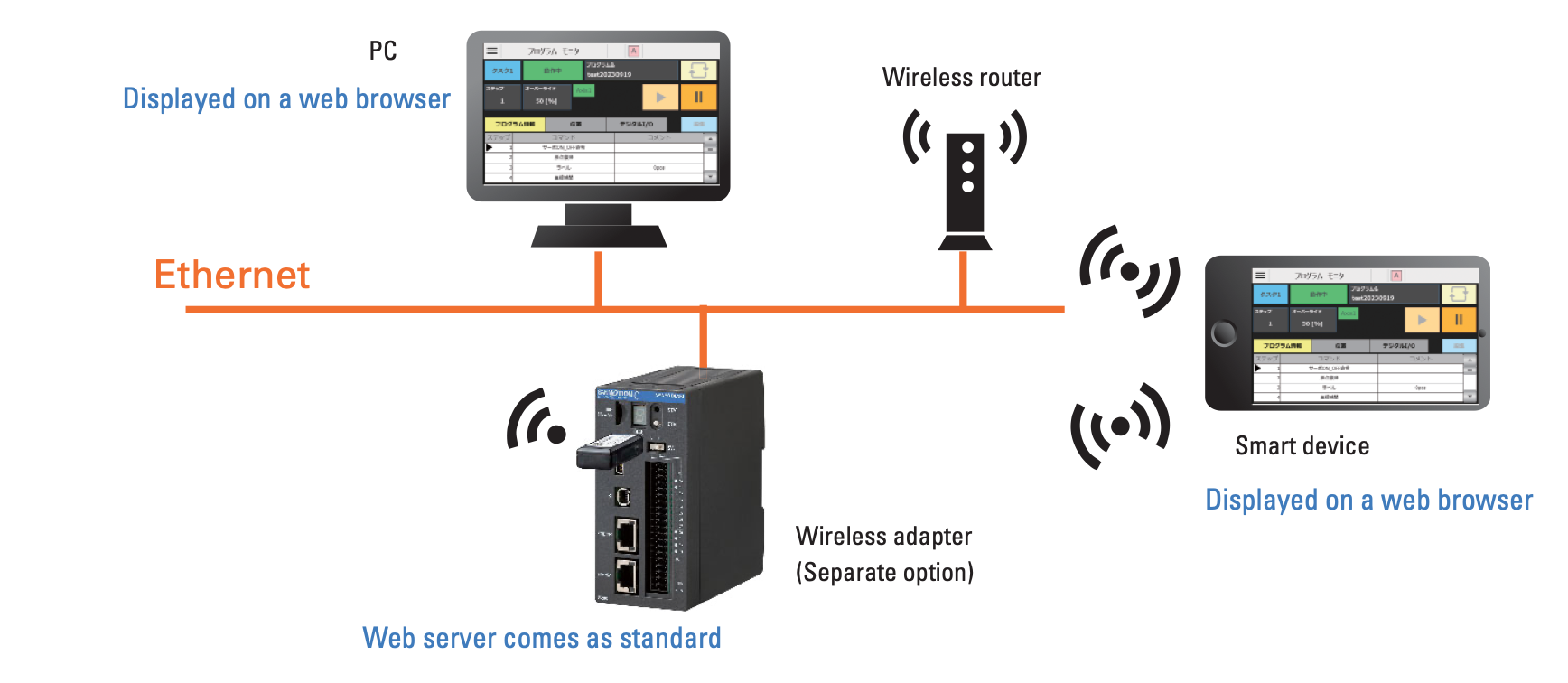

Additionally, SANMOTION motion controllers generate diagnostic signals and status flags that indicate the operational status of the system. These signals are communicated to supervisory systems or operators through HMI interfaces, which enable real-time monitoring and troubleshooting.

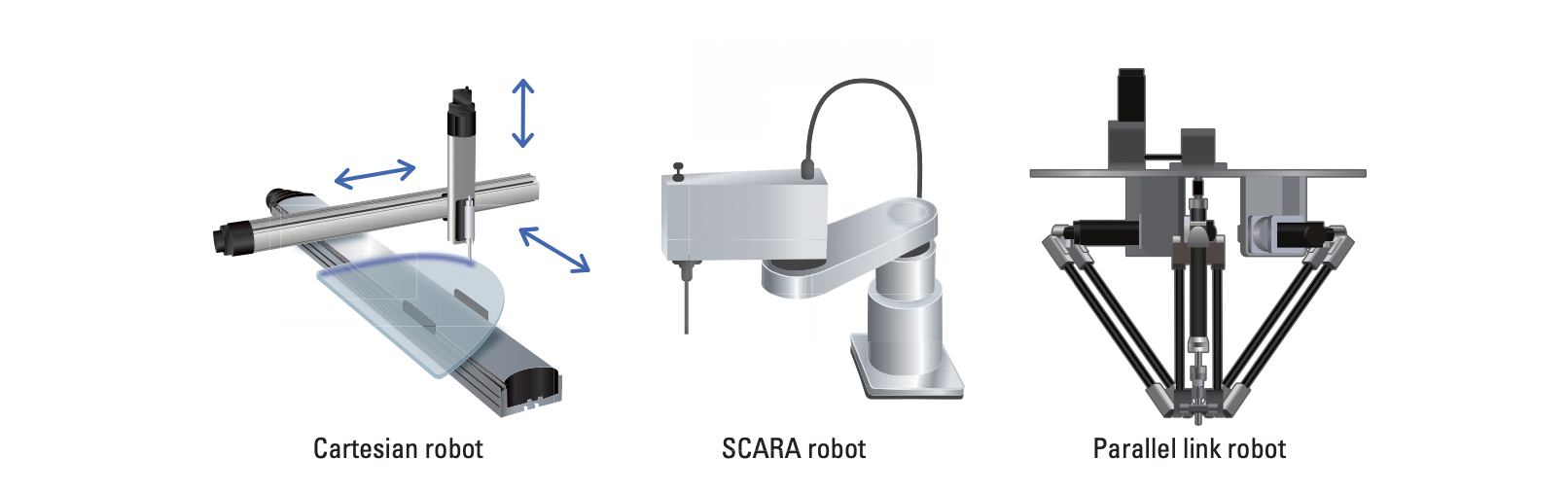

G-code (DIN 66025 compliant) enables control of various robot mechanisms such as cartesian, SCARA, and delta robots.

SANMOTION motion controllers include a CNC function that generates and executes motion profiles and trajectory plans for actuators and robots. This function reads the desired motion trajectory from a CAD (DXF file) drawing and moves the components along predefined paths. This program-less system can significantly reduce development times and provide real-time insights into the production progress and status.

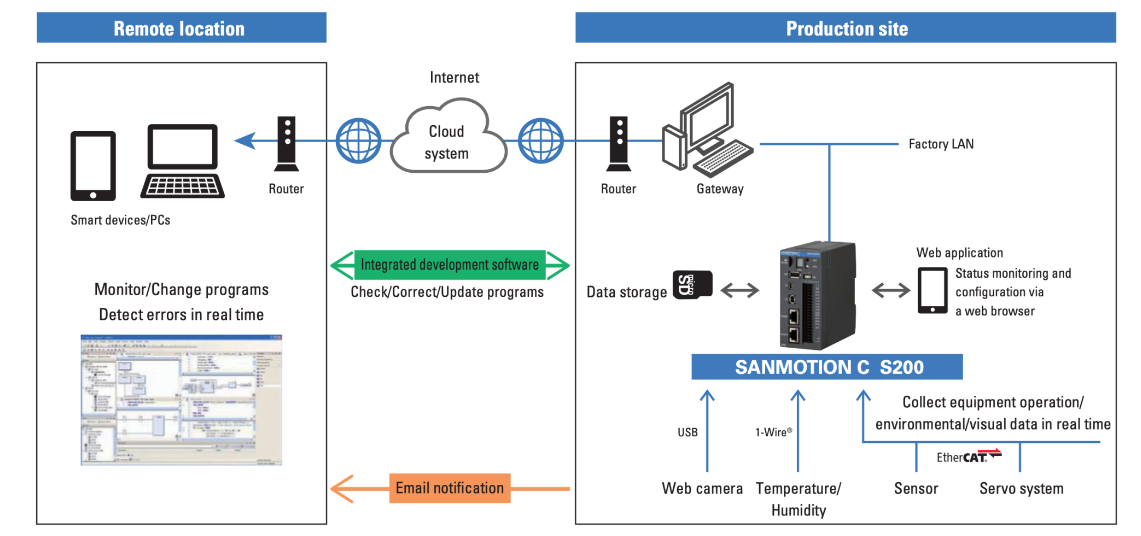

Moreover, SANMOTION motion controllers integrate with SCADA or MES software, which provide real-time production monitoring, reporting, and analysis capabilities. These software collect data from motion controllers and other production equipment and visualize production status, track performance metrics, and identify inefficiencies. (Learn more about ISA-95 systems integration.)

SANMOTION motion controllers generate alarms and events based on predefined conditions. Real-time monitoring of these alarms allows operators to promptly respond to abnormal conditions and minimize downtime.

In conclusion, SANMOTION motion controllers actively contribute to customers’ manufacturing operations in the Industry 4.0 landscape. By providing remote monitoring capabilities, SANMOTION enables proactive maintenance, troubleshooting, and optimization of production processes, ensuring agility and innovation in manufacturing.

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.