Development of the Batteryless "HA035" Absolute Encoder

Machine tools, industrial robots, and equipment such as injection molding machines that support the world’s manufacturing industries must have high precision positioning to create precision parts. As such, the encoder, which detects the position of the servo motor installed on machinery and equipment, is taking on an even more important role. Machining equipment, which is best represented by machine tools, produces precision parts, and therefore requires high accuracy and smooth positioning.

Machine tools, industrial robots, and equipment such as injection molding machines that support the world’s manufacturing industries must have high precision positioning to create precision parts. As such, the encoder, which detects the position of the servo motor installed on machinery and equipment, is taking on an even more important role. Machining equipment, which is best represented by machine tools, produces precision parts, and therefore requires high accuracy and smooth positioning.

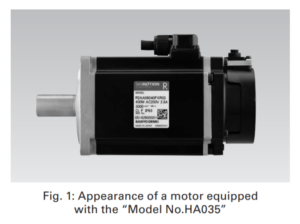

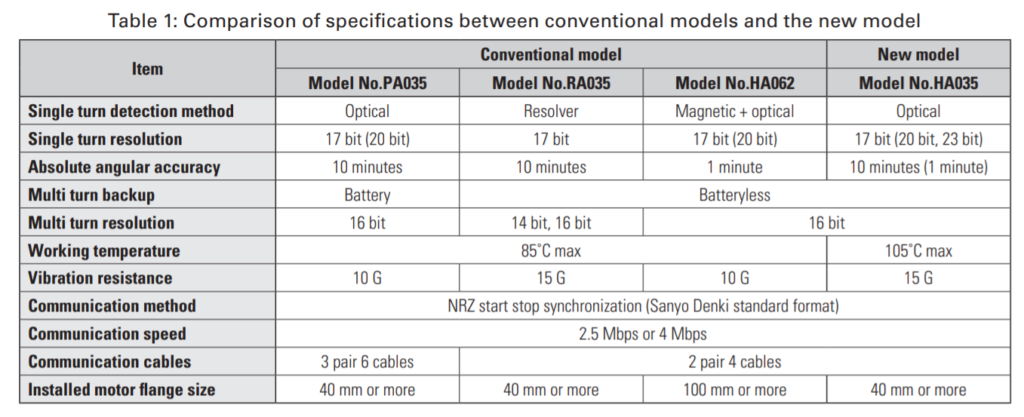

The “HA035” that we have developed this time is a small, high accuracy, batteryless encoder that can be installed on our R series servo motors with a flange size of 40 mm or more and is being presented as the new standard encoder to replace the “PA035”. The “HA035” has an absolute angular accuracy of 1 arc-minute and a maximum resolution of 23 bits, making it more accurate with higher resolution than conventional models. Moreover, it also has improved environmental resistance, with a maximum working temperature of 105˚C and vibration resistance of 15 G.

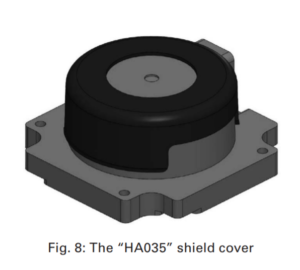

Unique Encoder Cover Structure

Generally-speaking, encoders which use magnetic elements are easily affected by external magnetic fields. The structure to block external magnetic fields must be arranged so as not to affect the magnetic circuit of the magnetic element. In large motors with ample room, it is possible to eliminate impact by leaving enough distance, however this is difficult in small motors with limited room. Fig. 8 shows the shield cover structure of the “HA035”. For the “HA035”, a hole has been opened in the top of the shield cover, and cut-outs have been made in either side; resulting in a very unique cover structure. With this type of shield structure, external magnetic fields are blocked but the encoder’s magnetic circuit is not affected. This unique shield cover structure ensures our customers can use the “HA035” with peace-of-mind, even in environments with external magnetic fields.

Generally-speaking, encoders which use magnetic elements are easily affected by external magnetic fields. The structure to block external magnetic fields must be arranged so as not to affect the magnetic circuit of the magnetic element. In large motors with ample room, it is possible to eliminate impact by leaving enough distance, however this is difficult in small motors with limited room. Fig. 8 shows the shield cover structure of the “HA035”. For the “HA035”, a hole has been opened in the top of the shield cover, and cut-outs have been made in either side; resulting in a very unique cover structure. With this type of shield structure, external magnetic fields are blocked but the encoder’s magnetic circuit is not affected. This unique shield cover structure ensures our customers can use the “HA035” with peace-of-mind, even in environments with external magnetic fields.

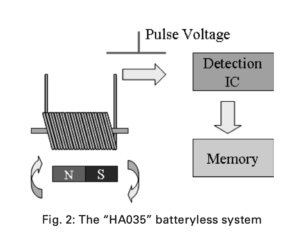

Eliminating External Power for Encoder Feedback

For the conventional “RA035” and “HA062” encoders, a combination of gears was used to hold multi-turn information. For this reason, downsizing was difficult due to the amount of space required for the gears, therefore the height of the “RA035” became greater and the “HA062” could only be fitted on motors with flange sizes of 100 mm or more. On the “HA035” however, we succeeded in downsizing by newly adopting a batteryless system utilizing induced voltage with a special magnetic element. Fig. 2 shows the configuration of a batteryless system. There are only two basic components; a coil which is mounted on the circuit board and a magnet which is attached to the tip of the shaft. The basic principle of this system is that pulse-shaped voltage is induced from the coil to suit the magnet rotation, this pulse is detected and stored the data in the nonvolatile memory. The power necessary at this time is supplied from the pulse-shaped inducted voltage, therefore operation is possible without the need for an external power supply.

For the conventional “RA035” and “HA062” encoders, a combination of gears was used to hold multi-turn information. For this reason, downsizing was difficult due to the amount of space required for the gears, therefore the height of the “RA035” became greater and the “HA062” could only be fitted on motors with flange sizes of 100 mm or more. On the “HA035” however, we succeeded in downsizing by newly adopting a batteryless system utilizing induced voltage with a special magnetic element. Fig. 2 shows the configuration of a batteryless system. There are only two basic components; a coil which is mounted on the circuit board and a magnet which is attached to the tip of the shaft. The basic principle of this system is that pulse-shaped voltage is induced from the coil to suit the magnet rotation, this pulse is detected and stored the data in the nonvolatile memory. The power necessary at this time is supplied from the pulse-shaped inducted voltage, therefore operation is possible without the need for an external power supply.

[…] high-precision battery-less absolute encoder Model No. HA035 comes equipped with our servo motors as standard. It does not require a battery, a periodic […]

[…] To learn more about the development and the new features of our latest absolute encoder, read our post, “Cut Downtime Maintenance with The HA035 Batteryless Encoder“ […]

[…] Cut Downtime Maintenance with The HA035 Batteryless Encoder […]