Motion Control Technology by SANYO DENKI AMERICA

SANYO DENKI's Insights on motion control, automation, and precision engineering.

As an equipment manufacturer, you understand the challenges—balancing optimal performance, reliability, and cost-effectiveness. This article unveils a pivotal solution to enhance your machinery’s lifespan, mitigate maintenance costs, and elevate user satisfaction. Dive into the additional benefits of our new stepper drivers, specifically engineered for extended equipment life, reduced downtime, and a quieter, more efficient workplace.

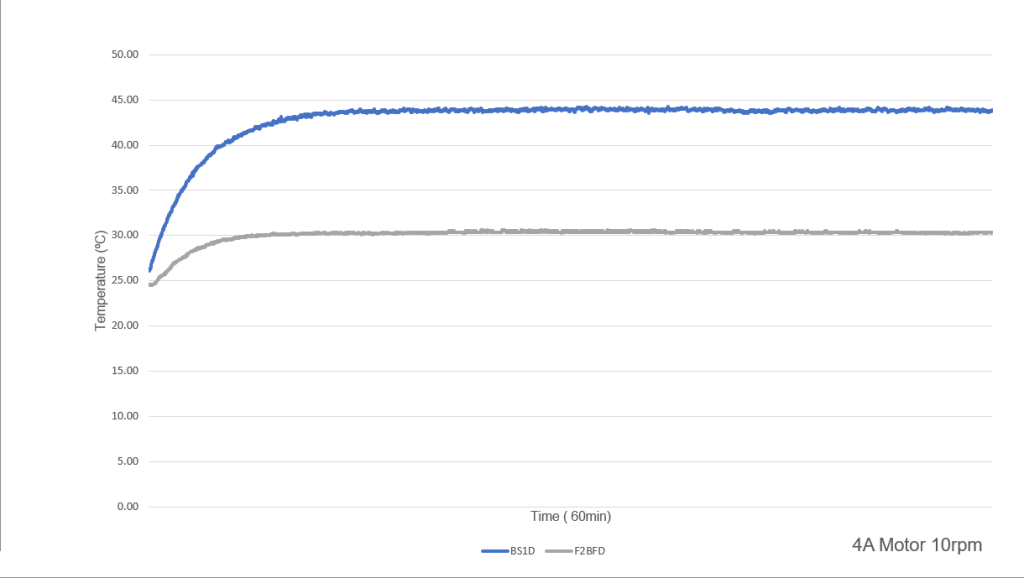

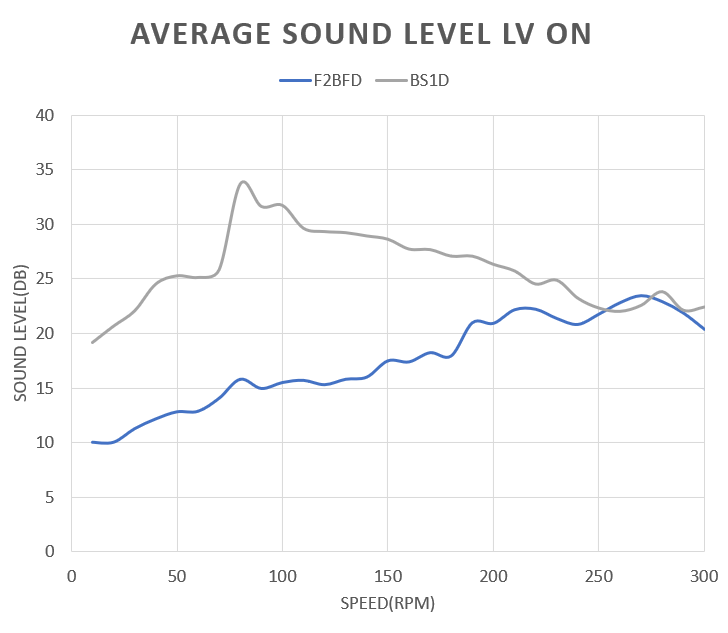

We conducted tests comparing the temperature rise and sound levels of two of our prominent stepper driver models—BS1D and the latest F2BFD. The results are not just numbers; they represent a leap forward in performance, ensuring a superior experience for equipment makers and end-users alike.

Our temperature rise comparison between the previous model, BS1D, and the new model, F2BFD, reveals a striking difference. The F2BFD showcases exceptional thermal performance, maintaining a steady 30°C during operation. In contrast, the BS1D exhibits a temperature rise nearing 44°C. That is 47% lower in comparison. This data underscores the superior temperature performance of the F2BFD, translating to enhanced reliability and prolonged equipment life. Next, I will explain each benefit more closely.

Beyond temperature, we delved into sound level performance, a crucial factor in noise-sensitive environments. The F2BFD demonstrated a smooth and steady sound level curve, devoid of spikes, even at higher speeds. The previous model, BS1D, exhibited a spike around 80 RPM, while the F2BFD showed a mild increase until around 270 RPM, it then started to decrease. This nuanced comparison highlights the F2BFD’s ability to provide a quieter and more consistent user experience, especially in applications where noise levels matter.

In precision-driven industries, our F2BFD stepper driver extends equipment life and enhances workplace comfort with its low-temperature rise and noise levels. Offering a practical and effective solution, it ensures cost-effective operation, marked by reduced maintenance, minimized downtime, and improved energy efficiency—an advancement in motion control technology.

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.