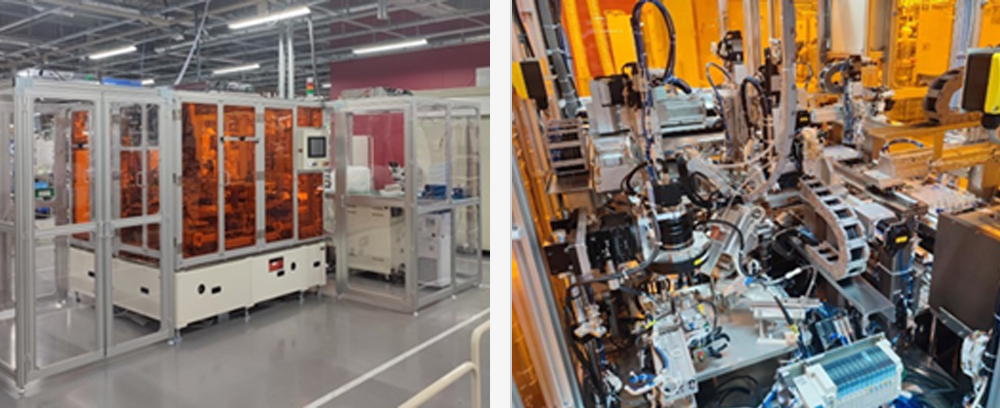

SANYO DENKI recently undertook a major initiative to establish an advanced production line at its main factory. The primary goal was to automate the assembly process of disc modules for encoders, with a focus on achieving precise performance, stable quality, and enhanced efficiency. Through strategic in-house production and the integration of the SANMOTION G servo motor, the production engineering team achieved noteworthy outcomes.

Addressing the Challenge: Automating Disc Module Assembly for Encoders

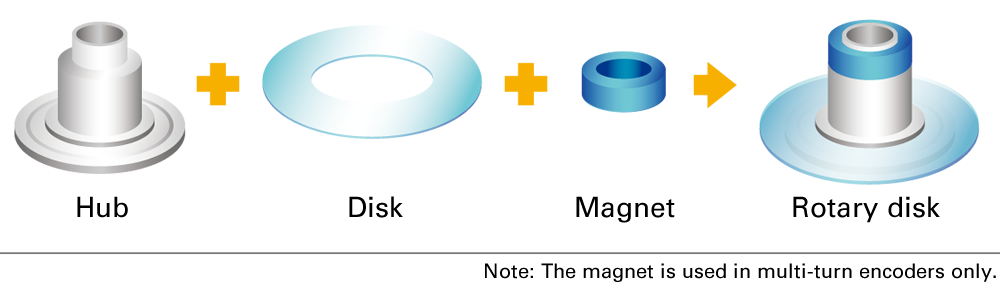

The production innovation line aimed to automate the labor-intensive assembly of disc modules for encoders, which demanded specialized expertise. One critical process required aligning the center axis of the hub precisely with the center axis of the disc. To achieve this, a camera was employed to recognize minute errors in the pattern printed on the disc. The detected misalignments were then corrected during the assembly process. Previously, this task was performed visually using a microscope, calling for a skill level at the micron-order range. The successful positioning of this compensated position relied on a high-resolution motor, while high-precision motor control ensured the dispenser applied the adhesive at the targeted position.

Development of In-House Assembly Equipment

Opting for in-house production over outsourcing, SANYO DENKI took on the challenge of developing in-house assembly equipment for encoders. The decision was driven by the need for precision and led to significant benefits in cost reduction and stable supply. Although faced with initial difficulties in reproducing skilled workers’ precision, the production engineering team persevered in their pursuit.

Leveraging SANMOTION G Servo Motor

The SANMOTION G servo motor, equipped with a 23-bit encoder, provided exceptional positioning accuracy, resulting in precise alignments during the assembly process.

* 23-bit is an accuracy that enables positioning at an angle of approximately 8.3 millionths of a revolution.

Overview of Equipment

Automated the process of disc module assembly to inspection

The automated disc module assembly equipment for encoders efficiently performs the following processes:

High-precision positioning and adhesive application: Employing advanced image processing, the equipment precisely positions the disc and hub while automatically applying two types of adhesives to ensure robust bonding.

Ring magnet insertion and curing: The equipment accurately inserts the ring magnet into the hub and follows an automated curing process within a rotary heating furnace.

Automatic inspection: After magnetization of the ring magnet, the equipment conducts an automatic inspection, assessing disc surface blur and magnet flux density.

Servo Axis Configuration

Transfer axes: 30

Rotary axes: 5

Total axes: 35

The Remarkable Results

Integrating the SANMOTION G servo motor and developing in-house assembly equipment for encoders yielded significant outcomes:

- Stable supply of discs: The automation process ensured a consistent and reliable supply of discs, successfully meeting demand.

- Enhanced processing quality: The combination of high-resolution positioning and improved adhesive application led to notable enhancements in overall processing quality.

- Reduced cycle time: The seamless integration of the SANMOTION G servo motor drastically reduced the cycle time, boosting productivity and streamlining production operations.

Conclusion

The success of the production innovation line has motivated SANYO DENKI’s production engineers to enthusiastically pursue ambitious projects aimed at expanding automated assembly equipment capabilities.

If you’re interested in learning more about SANMOTION G, be sure to check out articles below.

Request a Consultation

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.