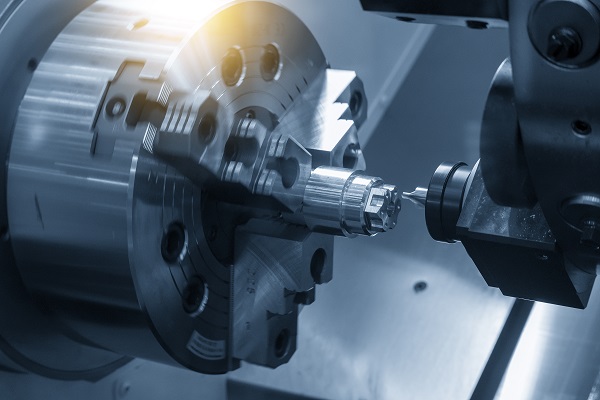

In the manufacturing industry, solving complex problems and enhancing machine tool performance requires a deep understanding of customer needs. This case study explores a real-life example where collaboration and profound knowledge of customer equipment led to the development of a specialized servo motor for driving machining center spindles. Let’s delve into the notable achievements in energy efficiency, acceleration, and environmental durability through high-speed technology and customized servo solutions.

1: Introducing the Servo Motor for Machining Center Spindles

To meet the demands of machining center spindles, which necessitate variable speed operation, high-torque performance, and efficient acceleration and deceleration, a novel approach was required. The primary focus was on minimizing power loss and improving energy-saving processing.

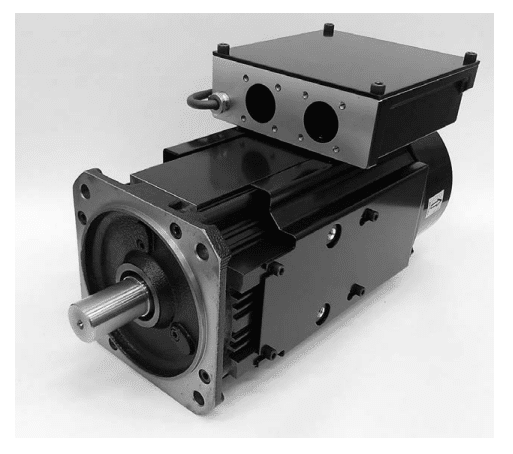

To address the complex requirements, a high-torque, low-inertia servo motor specialized in driving machine tool spindles was developed. This servo motor incorporated an interior permanent magnet (IPM) synchronous motor, where the permanent magnet was embedded into the rotor. By utilizing relatively less magnet material, this design enabled high torque delivery in the high-speed range while maintaining exceptional efficiency with minimal power loss.

The IPM motor’s unique characteristics allowed it to generate both torque from the permanent magnet and reluctance torque from the difference in rotor magnetic reluctance. This combination resulted in high torque delivery across a wide speed range, enabling the realization of a spindle servo motor with minimal power loss. Additionally, the motor facilitated variable speed operation up to an impressive 30,000 min-1.

To improve cycle time and reduce startup time, high-acceleration and deceleration operations were crucial. The new IPM motor was meticulously designed to minimize rotor moment of inertia while increasing torque, thus achieving outstanding acceleration and deceleration characteristics.

Power loss within the motor’s iron core typically increases at high speeds. To address this, the IPM motor underwent a redesign of its iron core shape and material, significantly minimizing iron loss at high speeds. Moreover, the motor’s reluctance torque was optimally controlled based on rotational speed, effectively reducing power loss and enhancing overall efficiency. With its low rotor moment of inertia, the motor consumed less power during acceleration and deceleration, contributing significantly to energy savings in machine tools.

Machine tools often employ cutting oil during machining processes, leading to oil scattering around the drive motors. To tackle this challenge, motor parts were constructed using materials with high oil resistance. The design also allowed for easy cleaning and replacement of cooling fans and components, ultimately improving environmental durability and reducing maintenance time.

The successful development of custom servo motors for machining center spindles showcased the power of collaboration and deep knowledge of customer equipment. Through cutting-edge technology and tailored solutions, this venture significantly improved machine tool performance, energy efficiency, and environmental durability. By focusing on customer-centric approaches, manufacturers can continue to revolutionize the manufacturing industry, providing exceptional solutions for unique challenges.

Read more customization achievements from our white paper.

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.