SANMOTION R1 Series Low Inertia Servo Motors Improve Overall Performance And Efficiency Of The Robotic Arm

Using the SANMOTION R1 Series low inertia servo motors to drive robot arm gear heads offers several benefits that contribute to the overall performance and efficiency of the system. Here are some advantages of using low inertia servo motors in conjunction with gear heads:

8 Advantages of Using Low Inertia Servo Motors with Gear Heads

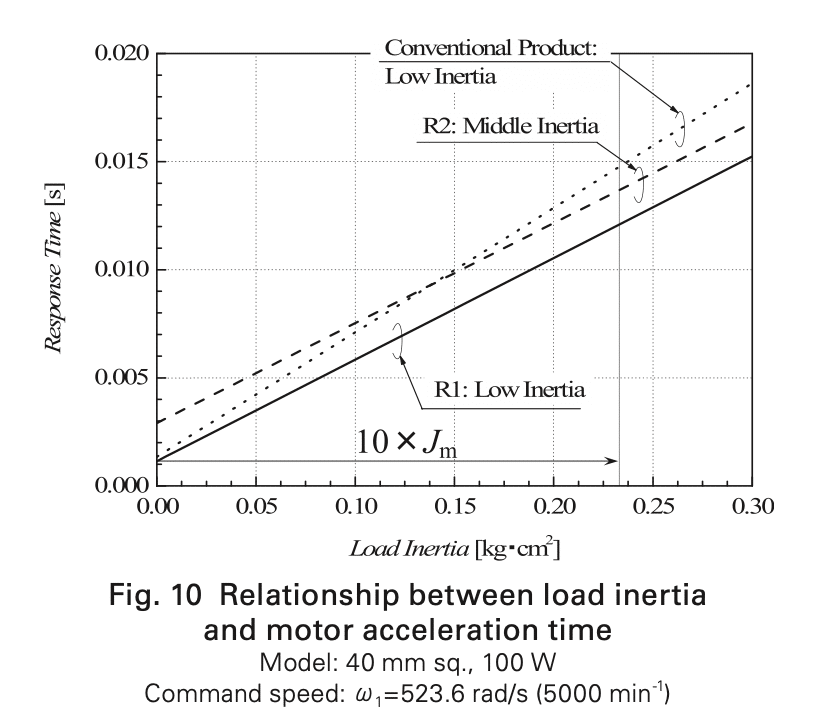

1. Faster response and agility: Low inertia servo motors have a lower mass and moment of inertia, which allows them to accelerate and decelerate more rapidly. In SANYO DENKI’s “Development Of the SANMOTION R1 Series” white paper, it’s described how this results in improved responsiveness and agility of the robot arm, enabling it to perform dynamic movements with greater speed and precision.

2. Enhanced control and accuracy: The low inertia of the servo motors reduces the mechanical lag between the control signal and the actual motion of the robot arm. This improves the accuracy and repeatability of movements, leading to more precise positioning and manipulation tasks.

3. Reduced overshoot and settling time: The combination of low inertia servo motors and gear heads enables faster and more precise adjustments, reducing overshoot and settling time. This is particularly beneficial in applications where the robot arm needs to stop precisely or change directions quickly.

4. Energy efficiency: Low inertia servo motors typically require less power to achieve the same level of performance compared to higher inertia motors. This energy efficiency translates to reduced power consumption, longer battery life, and lower operating costs in robotic systems.

5. Increased dynamic payload capacity: Low inertia servo motors can generate higher torque for their size, allowing the robot arm to handle larger dynamic payloads. This enables the arm to perform tasks that require moving or manipulating heavier objects while maintaining control and stability.

6. Improved vibration and noise characteristics: The low inertia and efficient control of servo motors contribute to smoother and quieter operation of the robot arm. This is particularly important in applications where noise reduction and minimal vibration are desired, such as in precision manufacturing or laboratory settings.

7. Compact and lightweight design: Low inertia servo motors are generally more compact and lightweight than their higher inertia counterparts. This attribute allows for a more compact and lightweight robot arm design, which is beneficial for applications with limited space or weight constraints.

8. High acceleration and deceleration capabilities: The low inertia nature of these servo motors enables rapid changes in acceleration and deceleration, making them suitable for applications that require quick and precise movements. This is advantageous in tasks such as pick-and-place operations or high-speed assembly lines.

By combining low inertia servo motors with gear heads in robot arm designs, the system can achieve faster response times, improved accuracy, energy efficiency, and increased payload capacity. These benefits contribute to the overall performance and effectiveness of the robot arm in various applications. You can follow a tutorial to learn how to configure a low inertia servo motor with a gear head or request a consultation with our sales and/or engineering support.

The Next-Gen AC Servo Systems SANMOTION G incorporates low inertial servo motors as well.

Request a Consultation

Request a consultation for your customization needs. Our team will be in contact with you soon to provide further information and answer any questions you may have.